Page 280 - Master Handbook of Acoustics

P. 280

FIGURE 12-26 Measured absorption of polycylindrical absorbers of various chord and height

dimensions. (A and B) Only empty poly data are available; the broken lines are estimated absorption

when filled with mineral wool. (C and D) Both empty polys and polys filled with mineral wool.

(Mankovsky.)

Poly Construction

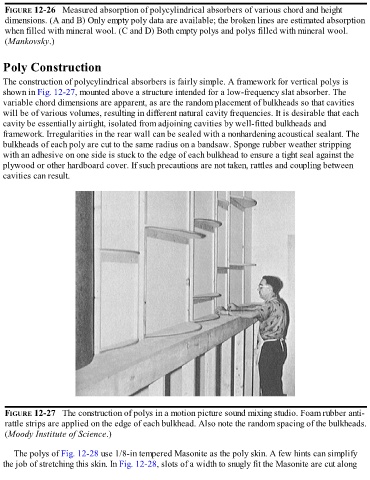

The construction of polycylindrical absorbers is fairly simple. A framework for vertical polys is

shown in Fig. 12-27, mounted above a structure intended for a low-frequency slat absorber. The

variable chord dimensions are apparent, as are the random placement of bulkheads so that cavities

will be of various volumes, resulting in different natural cavity frequencies. It is desirable that each

cavity be essentially airtight, isolated from adjoining cavities by well-fitted bulkheads and

framework. Irregularities in the rear wall can be sealed with a nonhardening acoustical sealant. The

bulkheads of each poly are cut to the same radius on a bandsaw. Sponge rubber weather stripping

with an adhesive on one side is stuck to the edge of each bulkhead to ensure a tight seal against the

plywood or other hardboard cover. If such precautions are not taken, rattles and coupling between

cavities can result.

FIGURE 12-27 The construction of polys in a motion picture sound mixing studio. Foam rubber anti-

rattle strips are applied on the edge of each bulkhead. Also note the random spacing of the bulkheads.

(Moody Institute of Science.)

The polys of Fig. 12-28 use 1/8-in tempered Masonite as the poly skin. A few hints can simplify

the job of stretching this skin. In Fig. 12-28, slots of a width to snugly fit the Masonite are cut along