Page 188 - Materials Chemistry, Second Edition

P. 188

175

3.1. Mining and Processing of Metals

this process is also useful to produce powders of difficult compositions. For instance,

copper–lead powders may not be formed through simple precipitation from liquid

solutions. Upon solidification, the lead will preferentially precipitate, resulting in a

copper-rich metallic powder. By comparison, atomization of a Cu/Pb molten

solution results in a copper powder containing a very fine and uniform distribution

of lead inclusions within each particulate.

For powder metallurgy, the density of the powder strongly influences the strength

of the material obtained from compaction. As one would expect, the density of the

powder depends on both the shape and porosity of individual micron-sized particu-

lates. We saw in Chapter 2 that close-packed metals will have higher densities than

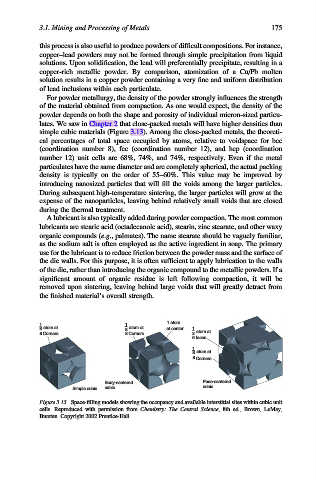

simple cubic materials (Figure 3.13). Among the close-packed metals, the theoreti-

cal percentages of total space occupied by atoms, relative to voidspace for bcc

(coordination number 8), fcc (coordination number 12), and hcp (coordination

number 12) unit cells are 68%, 74%, and 74%, respectively. Even if the metal

particulates have the same diameter and are completely spherical, the actual packing

density is typically on the order of 55–60%. This value may be improved by

introducing nanosized particles that will fill the voids among the larger particles.

During subsequent high-temperature sintering, the larger particles will grow at the

expense of the nanoparticles, leaving behind relatively small voids that are closed

during the thermal treatment.

A lubricant is also typically added during powder compaction. The most common

lubricants are stearic acid (octadecanoic acid), stearin, zinc stearate, and other waxy

organic compounds (e.g., palmates). The name stearate should be vaguely familiar,

as the sodium salt is often employed as the active ingredient in soap. The primary

use for the lubricant is to reduce friction between the powder mass and the surface of

the die walls. For this purpose, it is often sufficient to apply lubrication to the walls

of the die, rather than introducing the organic compound to the metallic powders. If a

significant amount of organic residue is left following compaction, it will be

removed upon sintering, leaving behind large voids that will greatly detract from

the finished material’s overall strength.

1 atom

1 1

8 atom at 8 atom at at center 1

8 Corners 8 Corners 2 atom at

6 faces

1

8 atom at

8 Corners

Body-centered Face-centered

Simple cubic cubic cubic

Figure 3.13. Space-filling models showing the occupancy and available interstitial sites within cubic unit

cells. Reproduced with permission from Chemistry: The Central Science, 8th ed., Brown, LeMay,

Bursten. Copyright 2002 Prentice-Hall.