Page 74 - Mechanical Behavior of Materials

P. 74

Section 3.3 Irons and Steels 73

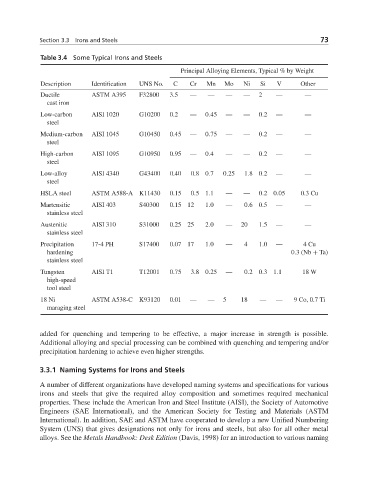

Table 3.4 Some Typical Irons and Steels

Principal Alloying Elements, Typical % by Weight

Description Identification UNS No. C Cr Mn Mo Ni Si V Other

Ductile ASTM A395 F32800 3.5 — — — — 2 — —

cast iron

Low-carbon AISI 1020 G10200 0.2 — 0.45 — — 0.2 — —

steel

Medium-carbon AISI 1045 G10450 0.45 — 0.75 — — 0.2 — —

steel

High-carbon AISI 1095 G10950 0.95 — 0.4 — — 0.2 — —

steel

Low-alloy AISI 4340 G43400 0.40 0.80.7 0.25 1.80.2 — —

steel

HSLA steel ASTM A588-A K11430 0.15 0.51.1 — — 0.20.05 0.3 Cu

Martensitic AISI 403 S40300 0.15 12 1.0 — 0.60.5 — —

stainless steel

Austenitic AISI 310 S31000 0.25 25 2.0 — 20 1.5 — —

stainless steel

Precipitation 17-4 PH S17400 0.07 17 1.0 — 4 1.0 — 4 Cu

hardening 0.3 (Nb + Ta)

stainless steel

Tungsten AISI T1 T12001 0.75 3.80.25 — 0.20.31.1 18 W

high-speed

tool steel

18 Ni ASTM A538-C K93120 0.01 — — 5 18 — — 9 Co, 0.7 Ti

maraging steel

added for quenching and tempering to be effective, a major increase in strength is possible.

Additional alloying and special processing can be combined with quenching and tempering and/or

precipitation hardening to achieve even higher strengths.

3.3.1 Naming Systems for Irons and Steels

A number of different organizations have developed naming systems and specifications for various

irons and steels that give the required alloy composition and sometimes required mechanical

properties. These include the American Iron and Steel Institute (AISI), the Society of Automotive

Engineers (SAE International), and the American Society for Testing and Materials (ASTM

International). In addition, SAE and ASTM have cooperated to develop a new Unified Numbering

System (UNS) that gives designations not only for irons and steels, but also for all other metal

alloys. See the Metals Handbook: Desk Edition (Davis, 1998) for an introduction to various naming