Page 165 - Mechanical Engineer's Data Handbook

P. 165

154 MECHANICAL ENGINEER’S DATA HANDBOOK

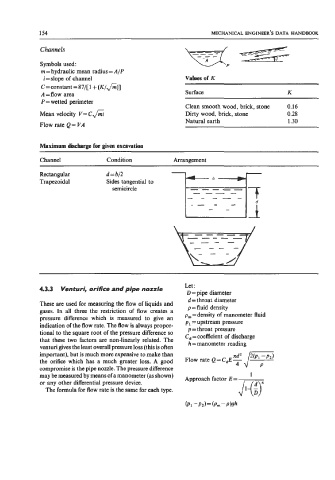

Channels

Symbols used :

m = hydraulic mean radius = A/P

i=slope of channel Values of K

C = constant = 87/[ 1 + (K/&)]

A=flow area Surface K

P = wetted perimeter

Mean velocity V= ~Jmr Clean smooth wood, brick, stone 0.16

0.28

Dirty wood, brick, stone

Natural earth 1.30

Flow rate Q= VA

Maximum discharge for given excavation

Channel Condition Arrangement

Rectangular d=b/2

Trapezoidal Sides tangential to

semicircle

Let :

4.3.3 Venturi, orifice and pipe nozzle

D = pipe diameter

d = throat diameter

These are used for measuring the flow of liquids and

p = fluid density

gases. In all three the restriction of flow creates a p, =density of manometer fluid

pressure difference which is measured to give an p1 =upstream pressure

indication of the flow rate. The flow is always propor- p = throat pressure

tional to the square root of the pressure difference so C, = coefficient of discharge

that these two factors are non-linearly related. The h = manometer reading

venturi gives the least overall pressure loss (this is often

important), but is much more expensive to make than Flow rate Q = C,E 4 /?

the orifice which has a much greater loss. A good

compromise is the pipe nozzle. The pressure difference

may be measured by means of a manometer (as shown)

or any other differential pressure device.

The formula for flow rate is the same for each type.