Page 259 - Mechanical Engineer's Data Handbook

P. 259

ENGINEERING MATERIALS 247

costly but will operate up to 200°C and is used for ‘foam’, a liquid rubber expanded to form open or

high-temperature seals and gaskets. closed cells and stiffer than sponge; and ‘expanded’, a

solid rubber blown with mainly closed cells - it is stiffer

Elastomers than sponge. Uses include gaskets, seals, thermal

insulation, cushioning, shock absorption, sound and

Cellular rubbers There are three types: ‘sponge‘, vibration damping, buoyancy and sandwich construc-

solid rubber blown to give an open-cell structure; tions.

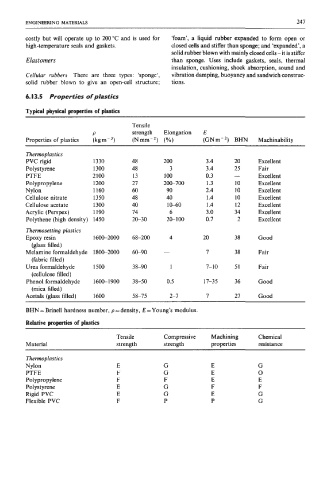

6.13.5 Properties of plastics

Typical physical properties of plastics

Tensile

P strength Elongation E

Properties of plastics (kg m- 3, (Nmm-’) (%) (GNm-2) BHN Machinability

Thermoplastics

PVC rigid 1330 48 200 3.4 20 Excellent

Polystyrene 1300 48 3 3.4 25 Fair

PTFE 2100 13 100 0.3 - Excellent

Polypropylene 1200 27 200-700 1.3 10 Excellent

Nylon 1160 60 90 2.4 10 Excellent

Cellulose nitrate 1350 48 40 1.4 10 Excellent

Cellulose acetate 1300 40 10-60 1.4 12 Excellent

Acrylic (Perspex) 1190 74 6 3 .O 34 Excellent

Polythene (high density) 1450 2&30 20-100 0.7 2 Excellent

Thermosetting plastics

Epoxy resin 1600-2000 68-200 4 20 38 Good

(glass filled)

Melamine formaldehyde 1800-2000 6&90 - 7 38 Fair

(fabric filled)

Urea formaldehyde 1500 38-90 1 7-10 51 Fair

(cellulose filled)

Phenol formaldehyde 160&1900 38-50 0.5 17-35 36 Good

(mica filled)

Acetals (glass filled) 1600 58-75 2-7 7 27 Good

BHN = Brinell hardness number, p =density, E = Young’s modulus.

Relative properties of plastics

Tensile Compressive Machining Chemical

Material strength strength properties resistance

Thermoplastics

Nylon G E

PTFE G E

Polypropylene F E

Polystyrene G F

Rigid PVC G E

Flexible PVC P P