Page 454 - Mechanical Engineers' Handbook (Volume 2)

P. 454

1 Introduction 445

1.1 Closed-Loop versus Open-Loop Control

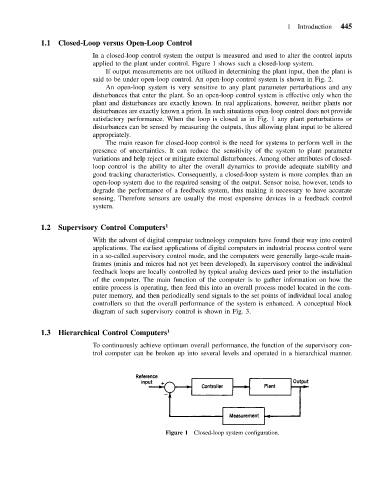

In a closed-loop control system the output is measured and used to alter the control inputs

applied to the plant under control. Figure 1 shows such a closed-loop system.

If output measurements are not utilized in determining the plant input, then the plant is

said to be under open-loop control. An open-loop control system is shown in Fig. 2.

An open-loop system is very sensitive to any plant parameter perturbations and any

disturbances that enter the plant. So an open-loop control system is effective only when the

plant and disturbances are exactly known. In real applications, however, neither plants nor

disturbances are exactly known a priori. In such situations open-loop control does not provide

satisfactory performance. When the loop is closed as in Fig. 1 any plant perturbations or

disturbances can be sensed by measuring the outputs, thus allowing plant input to be altered

appropriately.

The main reason for closed-loop control is the need for systems to perform well in the

presence of uncertainties. It can reduce the sensitivity of the system to plant parameter

variations and help reject or mitigate external disturbances. Among other attributes of closed-

loop control is the ability to alter the overall dynamics to provide adequate stability and

good tracking characteristics. Consequently, a closed-loop system is more complex than an

open-loop system due to the required sensing of the output. Sensor noise, however, tends to

degrade the performance of a feedback system, thus making it necessary to have accurate

sensing. Therefore sensors are usually the most expensive devices in a feedback control

system.

1.2 Supervisory Control Computers 1

With the advent of digital computer technology computers have found their way into control

applications. The earliest applications of digital computers in industrial process control were

in a so-called supervisory control mode, and the computers were generally large-scale main-

frames (minis and micros had not yet been developed). In supervisory control the individual

feedback loops are locally controlled by typical analog devices used prior to the installation

of the computer. The main function of the computer is to gather information on how the

entire process is operating, then feed this into an overall process model located in the com-

puter memory, and then periodically send signals to the set points of individual local analog

controllers so that the overall performance of the system is enhanced. A conceptual block

diagram of such supervisory control is shown in Fig. 3.

1.3 Hierarchical Control Computers 1

To continuously achieve optimum overall performance, the function of the supervisory con-

trol computer can be broken up into several levels and operated in a hierarchical manner.

Figure 1 Closed-loop system configuration.