Page 371 - Mechanical Engineers' Handbook (Volume 4)

P. 371

360 Heat Pipes

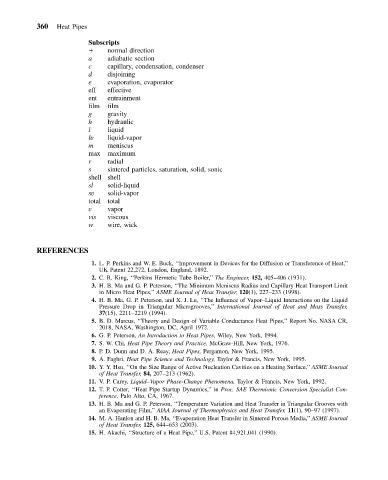

Subscripts

normal direction

a adiabatic section

c capillary, condensation, condenser

d disjoining

e evaporation, evaporator

eff effective

ent entrainment

film film

g gravity

h hydraulic

l liquid

lv liquid-vapor

m meniscus

max maximum

r radial

s sintered particles, saturation, solid, sonic

shell shell

sl solid-liquid

sv solid-vapor

total total

v vapor

vis viscous

w wire, wick

REFERENCES

1. L. P. Perkins and W. E. Buck, ‘‘Improvement in Devices for the Diffusion or Transference of Heat,’’

UK Patent 22,272, London, England, 1892.

2. C. R. King, ‘‘Perkins Hermetic Tube Boiler,’’ The Engineer, 152, 405–406 (1931).

3. H. B. Ma and G. P. Peterson, ‘‘The Minimum Meniscus Radius and Capillary Heat Transport Limit

in Micro Heat Pipes,’’ ASME Journal of Heat Transfer, 120(1), 227–233 (1998).

4. H. B. Ma, G. P. Peterson, and X. J. Lu, ‘‘The Influence of Vapor–Liquid Interactions on the Liquid

Pressure Drop in Triangular Microgrooves,’’ International Journal of Heat and Mass Transfer,

37(15), 2211–2219 (1994).

5. B. D. Marcus, ‘‘Theory and Design of Variable Conductance Heat Pipes,’’ Report No. NASA CR,

2018, NASA, Washington, DC, April 1972.

6. G. P. Peterson, An Introduction to Heat Pipes, Wiley, New York, 1994.

7. S. W. Chi, Heat Pipe Theory and Practice, McGraw-Hill, New York, 1976.

8. P. D. Dunn and D. A. Reay, Heat Pipes, Pergamon, New York, 1995.

9. A. Faghri, Heat Pipe Science and Technology, Taylor & Francis, New York, 1995.

10. Y. Y. Hsu, ‘‘On the Size Range of Active Nucleation Cavities on a Heating Surface,’’ ASME Journal

of Heat Transfer, 84, 207–213 (1962).

11. V. P. Carey, Liquid–Vapor Phase-Change Phenomena, Taylor & Francis, New York, 1992.

12. T. P. Cotter, ‘‘Heat Pipe Startup Dynamics,’’ in Proc. SAE Thermionic Conversion Specialist Con-

ference, Palo Alto, CA, 1967.

13. H. B. Ma and G. P. Peterson, ‘‘Temperature Variation and Heat Transfer in Triangular Grooves with

an Evaporating Film,’’ AIAA Journal of Thermophysics and Heat Transfer, 11(1), 90–97 (1997).

14. M. A. Hanlon and H. B. Ma, ‘‘Evaporation Heat Transfer in Sintered Porous Media,’’ ASME Journal

of Heat Transfer, 125, 644–653 (2003).

15. H. Akachi, ‘‘Structure of a Heat Pipe,’’ U.S. Patent #4,921,041 (1990).