Page 69 - Mechanics of Microelectromechanical Systems

P. 69

56 Chapter 1

define the three springs that characterize the lumped-parameter elastic model

of a cantilever, and is further employed in calculating the natural frequencies

of such a structure, the stiffnesses of Eq. (1.16) are the ones to be used when

calculating forces and moments that correspond to known tip deflections and

slopes. The difference between individual (definition) stiffnesses (denoted

with an upper bar, as shown in Eqs. (1.217) – this notation will be used from

this point on) and stiffnesses resulting from inversion of the compliance

matrix (which is unique for a given beam configuration) will become more

evident in Chapter 2 when studying microcantilever applications.

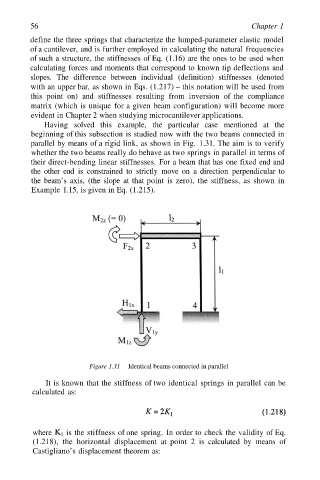

Having solved this example, the particular case mentioned at the

beginning of this subsection is studied now with the two beams connected in

parallel by means of a rigid link, as shown in Fig. 1.31. The aim is to verify

whether the two beams really do behave as two springs in parallel in terms of

their direct-bending linear stiffnesses. For a beam that has one fixed end and

the other end is constrained to strictly move on a direction perpendicular to

the beam’s axis, (the slope at that point is zero), the stiffness, as shown in

Example 1.15, is given in Eq. (1.215).

Figure 1.31 Identical beams connected in parallel

It is known that the stiffness of two identical springs in parallel can be

calculated as:

where is the stiffness of one spring. In order to check the validity of Eq.

(1.218), the horizontal displacement at point 2 is calculated by means of

Castigliano’s displacement theorem as: