Page 149 - Mechatronic Systems Modelling and Simulation with HDLs

P. 149

138 7 MECHATRONICS

C- oder Assembler-Programm:

RESET: Data 8

dw START

org $1000 Memory Adr CPU

START:

clra 16

sta DATA

sta STATE

sta IOPORT

LOOP:

jsr CALC RWb

bra LOOP Clk

end

... PIO

Control

Input

Output

Timer ADC DAC

Car body

acceleration

Desired

damping

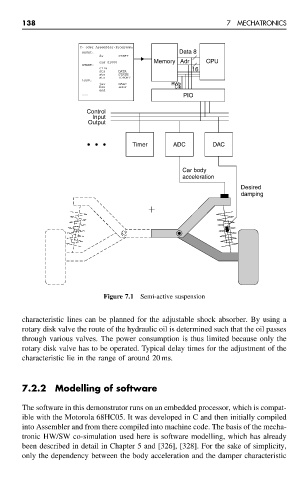

Figure 7.1 Semi-active suspension

characteristic lines can be planned for the adjustable shock absorber. By using a

rotary disk valve the route of the hydraulic oil is determined such that the oil passes

through various valves. The power consumption is thus limited because only the

rotary disk valve has to be operated. Typical delay times for the adjustment of the

characteristic lie in the range of around 20 ms.

7.2.2 Modelling of software

The software in this demonstrator runs on an embedded processor, which is compat-

ible with the Motorola 68HC05. It was developed in C and then initially compiled

into Assembler and from there compiled into machine code. The basis of the mecha-

tronic HW/SW co-simulation used here is software modelling, which has already

been described in detail in Chapter 5 and [326], [328]. For the sake of simplicity,

only the dependency between the body acceleration and the damper characteristic