Page 131 - Mechatronics for Safety, Security and Dependability in a New Era

P. 131

Ch24-I044963.fm Page 115 Monday, August 7, 2006 11:27 AM

Monday, August 7,2006

Page 115

Ch24-I044963.fm

11:27 AM

115

115

on for individual features [2].

(a) (b) Face 1 1

F a c e

(b)

Face 2

(c)

(c)

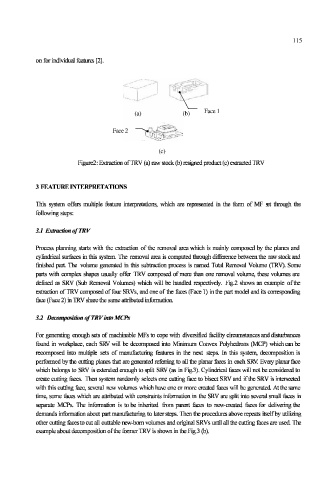

Figure2: Extraction of TRV (a) raw stock (b) resigned product (c) extracted TRV

3 FEATURE INTERPRETATIONS

This system offers multiple feature interpretations, which are represented in the form of MF st through the

following steps:

3.1 Extraction of TRV

Process planning starts with the extraction of the removal area which is mainly composed by the planes and

cylindrical surfaces in this system. The removal area is computed through difference between the raw stock and

finished part. The volume generated in this subtraction process is named Total Removal Volume (TRV). Some

parts with complex shapes usually offer TRV composed of more than one removal volume, these volumes are

defined as SRV (Sub Removal Volumes) which will be handled respectively. Fig.2 shows an example of the

extraction of TRV composed of four SRVs, and one of the iaces (Face 1) in the part model and its corresponding

face (Face 2) in TRV share the same attributed infbrmatioa

3.2 Decomposition ofTRVinto MCPs

For generating enough sets of machinable MFs to cope with diversified facility circumstances and disturbances

found in workplace, each SRV will be decomposed into Minimum Convex Polyhedrons (MCP) which can be

recomposed into multiple sets of manufacturing features in the next steps. In this system, decomposition is

performed by the cutting planes that are generated referring to all the planar faces in each SRV. Every planar face

which belongs to SRV is extended enough to split SRV (as in Fig.3). Cylindrical faces will not be considered to

create cutting faces. Then system randomly selects one cutting face to bisect SRV and if the SRV is intersected

with this cutting face, several new volumes which have one or more created faces will be generated. At the same

time, some faces which are attributed with constraints information in the SRV are split into several small iaces in

separate MCPs. The information is to be inherited from parent laces to new-created faces for delivering the

demands information about part manufacturing to later steps. Then the procedures above repeats itself by utilizing

other cutting facesto cut all cuttable new-born volumes and original SRVs until all the cutting faces are used The

example about decomposition of the former TRV is shown in the Fig.3 (b).