Page 20 - Mechatronics for Safety, Security and Dependability in a New Era

P. 20

Ch01-I044963.fm Page 4 Monday, August 7, 2006 11:24 AM

Ch0 1-I044963 .fm

4 Page 4 Monday, August 7, 2006 11:24 AM

V. DISCUSSION ON SUCCESSFULLY PUTTING SERVICE ROBOTS TO PRACTICAL USE

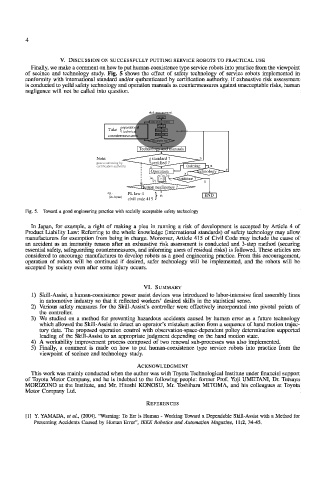

Finally, we make a comment on how to put human-coexistence type service robots into practice from the viewpoint

of sccincc and technology study. Fig. 5 shows the effect of safety technology of service robots implemented in

conformity with international standard and/or quthenticated by certification authority. If exhaustive risk assessment

is conducted to yeild safety technology and operation manuals as countermeasures against unacceptable risks, human

negligence will not be called into question.

risk assessment

START

Clarify operating condition

Find risk

operational

Take Estimate risk

technical

countermeasures Evaluate risk

acceptable risk ?

Technology and manuals

Note:

Note: standard ? n

pass a screening by

pass a screening by certified ?

certification

authority

certification authority y training n

technology ? y

y

> > >< >< > continue ?

Operation >

> > > > n

Human negligence ?

eg . PL law 4 T T END

eg.

PLlaw4

(in Japan)

(in Japan) P Lla w 4 , _ J n n

civil code 415

civil code 415

ode 415

Fig. 5. Toward a good engineering practice with socially acceptable safety technology

In Japan, for example, a right of making a pica in running a risk of development is accepted by Article 4 of

Product Liability Law: Referring to the whole knowledge (international standards) of safety technology may allow

manufacturers for exemption from being in charge. Moreover, Article 415 of Civil Code may include the cause of

an accident as an immunity reason after an exhaustive risk assessment is conducted and 3-step method (securing

essential safely, safeguarding counlcrmcasurcs, and informing users of residual risks) is followed. These articles arc

considered to encourage manufactures to develop robots as a good engineering practice. From this encouragement,

operation of robots will be continued if desired, safer technology will be implemented, and the robots will be

accepted by society even after some injury occurs.

VI. SUMMARY

1) Skill-Assist, a human-coexistence power assist devices was introduced to labor-intensive final assembly lines

in automotive industry so that it reflected workers' desired skills in the statistical sense.

2) Various safety measures for the Skill-Assist's controller were effectively incorporated into pivotal points of

the controller.

3) We studied on a method for preventing hazardous accidents caused by human error as a future technology

which allowed the Skill-Assist to delect an operator's mislaken action from a sequence of hand motion trajec-

tory data. The proposed operation control with observation-space-dependent policy determination supported

leading of the Skill-Assist to an appropriate judgment depending on the hand motion state.

4) A workability improvement process composed of two renewal sub-processes was also implemented.

5) Finally, a comment is made on how to put human-coexistence type service robots into practice from the

viewpoint of sceince and technology study.

ACKNOWLEDGMENT

This work was mainly conducted when the author was with Toyota Technological Institute under financial support

of Toyota Motor Company, and he is indebted to the following people: former Prof. Yoji UMETANI, Dr. Tetsuya

MORIZONO at the Institute, and Mr. Hitoshi KONOSU, Mr. Toshiharu MITOMA, and his colleagues at Toyota

Motor Company Ltd.

REFERENCES

[1] Y. YAMADA, e1 a/., (2004). "Warning: To Err is Human - Working Toward a Dependable Skill-Assist with a Method for

Preventing Accidents Caused by Human Error", IEEE Robotics and Automation Magazine, 11:2, 34-45.