Page 80 - Mechatronics for Safety, Security and Dependability in a New Era

P. 80

Ch14-I044963.fm Page 64 Tuesday, August 1, 2006 12:50 PM

Ch14-I044963.fm

64 64 Page 64 Tuesday, August 1,2006 12:50 PM

worker's behavior, estimate the operation time based on MTM(Method Time Measurement) ,

Maynard(1984), and assume the worker's posture at the virtual place. The process planner can analyze

the operation time and the worker's posture through the simulation, consider Kaizen ideas, and also

implement such ideas on the virtual manual operation process to confirm their effectiveness. However,

in the conventional 3-D computer simulation with the computer mannequin, e.g. Jack(UGS PLM

Solutions), DELIMA Ergo(Dassault Systems), it requires to teach the computer mannequin his tasks

from scratch in order to remodel the workplace tasks according to the Kaizen ideas. This modeling

takes a lot of time for trial and error. Therefore, using the conventional 3-D computer simulation with

the computer mannequin is tough for the process planner from a practical standpoint. In order to

reduce the remodeling time, this paper proposes a new modeling system, which enables users to

modify the workplace tasks easily and quickly. To confirm the efficiency of the proposed system, a

test case is tried out.

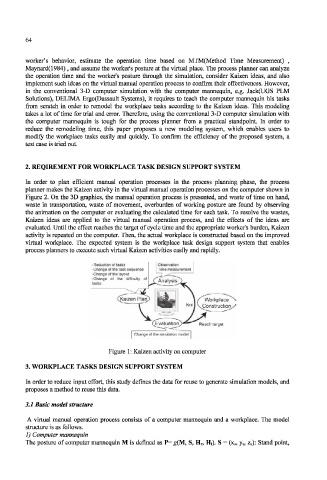

2. REQIREMENT FOR WORKPLACE TASK DESIGN SUPPORT SYSTEM

hi order to plan efficient manual operation processes in the process planning phase, the process

planner makes the Kaizen activity in the virtual manual operation processes on the computer shown in

Figure 2. On the 3D graphics, the manual operation process is presented, and waste of time on hand,

waste in transportation, waste of movement, overburden of working posture are found by observing

the animation on the computer or evaluating the calculated time for each task. To resolve the wastes,

Kaizen ideas are applied to the virtual manual operation process, and the effects of the ideas are

evaluated. Until the effect reaches the target of cycle time and the appropriate worker's burden, Kaizen

activity is repeated on the computer. Then, the actual workplace is constructed based on the improved

virtual workplace. The expected system is the workplace task design support system that enables

process planners to execute such virtual Kaizen activities easily and rapidly.

-Reduction of tasks Observation

-Change of the task sequence Time measurement

-Change of the layout

-Change of the difficulty of

tasks

Workplace

N o t

l V Construction

Reach target

Figure 1: Kaizen activity on computer

3. WORKPLACE TASKS DESIGN SUPPORT SYSTEM

hi order to reduce input effort, this study defines the data for reuse to generate simulation models, and

proposes a method to reuse this data.

S.I Basic model structure

A virtual manual operation process consists of a computer mannequin and a workplace. The model

structure is as follows.

1) Computer mannequin

The posture of computer mannequin M is defined as P= g(M, S, H r, Hi). S = (x s, y s, z s): Stand point,