Page 234 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 234

System design aids 203

0 5ppmBOD5,

0 10ppmCOD.

0 0 ppm salt, and

0 temperature of 12°C.

The cost price of this water is set at €0.1 per m3.

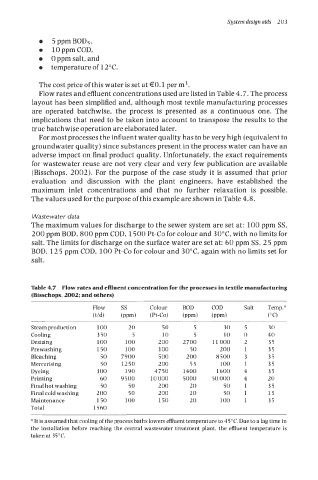

Flow rates and effluent concentrations used are listed in Table 4.7. The process

layout has been simplified and, although most textile manufacturing processes

are operated batchwise, the process is presented as a continuous one. The

implications that need to be taken into account to transpose the results to the

true batchwise operation are elaborated later.

For most processes the influent water quality has to be very high (equivalent to

groundwater quality) since substances present in the process water can have an

adverse impact on final product quality. Unfortunately, the exact requirements

for wastewater reuse are not very clear and very few publication are available

(Bisschops, 2002). For the purpose of the case study it is assumed that prior

evaluation and discussion with the plant engineers, have established the

maximum inlet concentrations and that no further relaxation is possible.

The values used for the purpose of this example are shown in Table 4.8.

Wastewater data

The maximum values for discharge to the sewer system are set at: 100 ppm SS,

200 ppm BOD, 800 ppm COD, 1500 Pt-Co for colour and 30°C with no limits for

salt. The limits for discharge on the surface water are set at: 60 ppm SS, 25 ppm

BOD, 125 ppm COD, 100 Pt-Co for colour and 30"C, again with no limits set for

salt.

Table 4.7 Flow rates and effluent concentration for the processes in textile manufacturing

(Bisschops, 2002; and others)

Steam production 100 20 50 5 30 5 30

Cooling 350 5 10 5 10 0 40

Desizing 100 100 200 2700 11000 2 35

Prewashing 150 100 100 50 200 1 35

Bleaching 50 7900 500 200 8500 3 35

Mercerising 50 1250 200 55 100 1 35

Dyeing 300 190 4750 1400 1600 4 35

Printing 60 9500 10000 5000 50000 4 20

Final hot washing 50 50 200 20 50 1 35

Final cold washing 200 50 200 20 50 1 15

Maintenance 150 100 150 20 100 1 35

Total 1560

a It is assumed that cooling of the process baths lowers effluent temperature to 45°C. Due to a lag time in

the installation before reaching the central wastewater treatment plant, the effluent temperature is

taken at 35°C.