Page 119 - Methods For Monitoring And Diagnosing The Efficiency Of Catalytic Converters A Patent - oriented Survey

P. 119

Toyota Motor Co. Ltd. 101

b) detecting an amount of intake air flow of the engine, and determining

that the engine operating conditions are not appropriate for said

determination of the deterioration of the three-way catalyst when

said amount of intake air flow of the engine becomes smaller than a

predetermined value.

I c

stoic h io mefri- I nnlcal

airfluel ratio 1

I

I : upstream sensor

:

.I----. downstream sensor

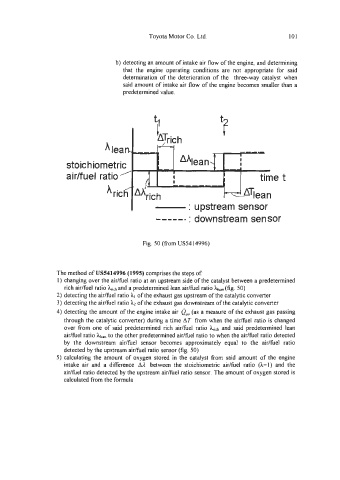

Fig. 50 (from US541 4996)

The method of US5414996 (1995) comprises the steps of

1) changing over the aidfuel ratio at an upstream side of the catalyst between a predetermined

rich aidfuel ratio Lch and a predetermined lean aidfuel ratio hr., (fig. 50)

2) detecting the aidfuel ratio AI of the exhaust gas upstream of the catalytic converter

3) detecting the aidfuel ratio of the exhaust gas downstream of the catalytic converter

4) detecting the amount of the engine intake air Ooir (as a measure of the exhaust gas passing

through the catalytic converter) during a time AT from when the air/fuel ratio is changed

over from one of said predetermined rich aidfuel ratio Lilich and said predetermined lean

aidfuel ratio kcan to the other predetermined aidfuel ratio to when the aidfuel ratio detected

by the downstream aidfuel sensor becomes approximately equal to the air/fuel ratio

detected by the upstream aidfuel ratio sensor (fig. 50)

5) calculating the amount of oxygen stored in the catalyst from said amount of the engine

intake air and a difference AA between the stoichiometric air/fuel ratio @=I) and the

air/fuel ratio detected by the upstream air/fuel ratio sensor. The amount of oxygen stored is

calculated from the formula