Page 225 - Methods For Monitoring And Diagnosing The Efficiency Of Catalytic Converters A Patent - oriented Survey

P. 225

Chapter 1.14

General Motors Corp.

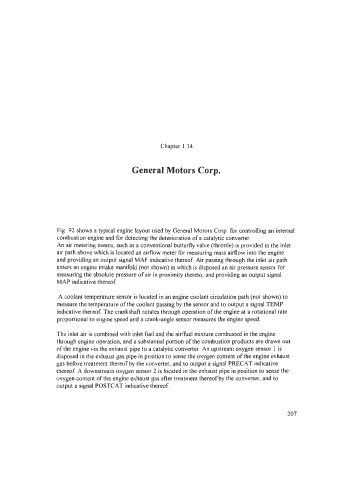

Fig. 92 shows a typical engine layout used by General Motors Corp. for controlling an internal

combustion engine and for detecting the deterioration of a catalytic converter.

An air metering means, such as a conventional butterfly valve (throttle) is provided in the inlet

air path above which is located an airflow meter for measuring mass airflow into the engine

and providing an output signal MAF indicative thereof. Air passing through the inlet air path

enters an engine intake manifold (not shown) in which is disposed an air pressure sensor for

measuring the absolute pressure of air in proximity thereto, and providing an output signal

MAP indicative thereof.

A coolant temperature sensor is located in an engine coolant circulation path (not shown) to

measure the temperature of the coolant passing by the sensor and to output a signal TEMP

indicative thereof. The crankshaft rotates through operation of the engine at a rotational rate

proportional to engine speed and a crank-angle sensor measures the engine speed.

The inlet air is combined with inlet fuel and the aidfuel mixture combusted in the engine

through engine operation, and a substantial portion of the combustion products are drawn out

of the engine via the exhaust pipe to a catalytic converter. An upstream oxygen sensor 1 is

disposed in the exhaust gas pipe in position to sense the oxygen content of the engine exhaust

gas before treatment thereof by the converter, and to output a signal PREXAT indicative

thereof A downstream oxygen sensor 2 is located in the exhaust pipe in position to sense the

oxygen content of the engine exhaust gas after treatment thereof by the converter, and to

output a signal POSTCAT indicative thereof.

207