Page 233 - A Practical Guide from Design Planning to Manufacturing

P. 233

Circuit Design 205

Instead, research is focusing on new high-K materials that will increase

the oxide permittivity. Charge mobility is improved by strained silicon

processes, which either push the silicon atoms in PMOS channels closer

together or pull the atoms in NMOS channels apart. For all silicon

MOSFETs, the mobility of holes in PMOS devices is only about half the

mobility of electrons in NMOS devices. The movement of holes is caused

by the movement of electrons in the opposite direction, but because

many different electrons are involved in moving a single hole, the process

is much less efficient than NMOS devices where each charge carrier is

a single free electron. To make up for the difference in mobility, circuit

designers routinely make the width of PMOS devices double the width

of NMOS devices.

Another important difference between NMOS and PMOS devices is

their ability to pull their drain terminals all the way up to the supply

voltage (usually written as V ) or down to the ground voltage (usually

dd

written as V ). Because NMOS devices will switch off if both source and

ss

drain are within a threshold voltage of the gate, an NMOS with its gate

tied to the supply voltage cannot pull its drain to the supply voltage. The

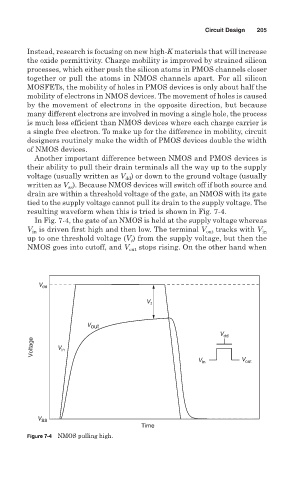

resulting waveform when this is tried is shown in Fig. 7-4.

In Fig. 7-4, the gate of an NMOS is held at the supply voltage whereas

V is driven first high and then low. The terminal V out tracks with V in

in

up to one threshold voltage (V ) from the supply voltage, but then the

t

NMOS goes into cutoff, and V out stops rising. On the other hand when

V dd

V t

V out

V dd

Voltage V in

V in V out

V ss

Time

Figure 7-4 NMOS pulling high.