Page 120 - Microtectonics

P. 120

108 4 · Foliations, Lineations and Lattice Preferred Orientation

4.4.4.2 Box 4.10 Problems with the interpretation of shear

The Effects of Strain and Recrystallisation sense using quartz LPO

The reader should be aware of possible pitfalls in the assess-

Increasing strain at constant flow parameters and tempera-

ment of shear sense using quartz LPO. First, the shear sense

ture will theoretically lead to strengthening of an LPO pat- observed may not be associated with the other fabric elements

tern (Fig. 4.41; Lister and Hobbs 1980), but fabric geometry visible in the rock. For example, where thin quartz seams oc-

may also change with increasing strain. The opening an- cur between other mineral grains, the flow kinematics may

gle of small circle girdles of c-axes in Type I crossed girdles have been completely different from the bulk flow. Another

possible error occurs at high strain, if fabrics are vague or

of a flattening progressive deformation regime (Fig. 4.41a)

incomplete, e.g. due to recrystallisation or the presence of

may decrease with increasing strain if dynamic recrys- grains of a second mineral. In this case, the orientation of the

tallisation is subdued; low temperature and high strain LPO pattern with respect to a reference foliation S r that is ap-

rate also produce relatively small opening angles (Tullis et al. proximately parallel to the fabric attractor will give the wrong

1973; Marjoribanks 1976; Jessell 1988b). This is an effect shear sense if it is interpreted as an external asymmetry

(Fig. B.4.6). It is therefore wise not to rely exclusively on quartz

of the competition of grain rotation in response to disloca-

c-axis fabrics to determine shear sense.

tion glide and dynamic recrystallisation. Small circle gir-

dles of c-axes are mostly due to grains with basal slip planes

at 45° to the shortening ISA; these grains have high resolved

shear stress on the slip system and are in optimal orien-

tation for ‘easy slip’. However, the slip planes in such grains

rotate away from this orientation towards the fabric

attractor with increasing strain, causing a decrease in the

opening angle of the small circle girdle (Fig. 4.39). High

temperature and low strain rate promote grain boundary

migration that may consume grains that have rotated to-

wards the shortening direction and this may hamper the

decrease in the opening angle with increasing strain.

There are also indications that single c-axis girdles Fig. B.4.6. a Contoured LPO pattern of quartz c-axes with a clear

with external asymmetry can form in simple shear internal asymmetry and external asymmetry with respect to S r

through an intermediate stage with symmetric crossed indicating dextral shear sense. b A similar pattern but more

vague so that it lost its internal asymmetry, and at high finite

girdles (Fig. 4.44; Garcia Celma 1982, 1983; Schmid and strain for dextral shear sense when S and L are approximately

r

r

Casey 1986; Herwegh et al. 1997). This effect may be due parallel to the fabric attractor. The pattern in b could be mis-

to an increasing effect of dynamic recrystallisation on de- taken for external asymmetry of a single girdle oblique to S at

r

velopment of LPO patterns with increasing strain; the low strain, and erroneously interpreted to represent a sinistral

change in fabric can be due to selective removal of grains shear sense. Black solid line and dots represent S r and L r . The

grey line marks the fabric attractor plane

in unfavourable orientations for slip by recrystallisation

(Schmid and Casey 1986; Jessell 1988a,b). A change in LPO

pattern geometry similar to that shown in Fig. 4.44 may 4.4.4.3

occur in transition between pure shear and simple shear Shear Sense Determination Using Quartz Fabrics

progressive deformation (Schmid and Casey 1986).

Patterns of c- and <a>-axes of quartz obtain an asymme-

try (actually a monoclinic symmetry) when they accu-

mulate by non-coaxial progressive deformation, and this

asymmetry can be used to deduce sense of shear. There

are two elements; some patterns, such as the skewed Type I

c-axis crossed girdles, have an internal asymmetry, inde-

pendent of other fabric elements (Fig. 4.42). More impor-

tant, however, is an external asymmetry of the patterns

with respect to S and L in the rock (Fig. 4.42). <a>-Axes

r

r

cluster near the fabric attractor, and c-axes in a girdle nor-

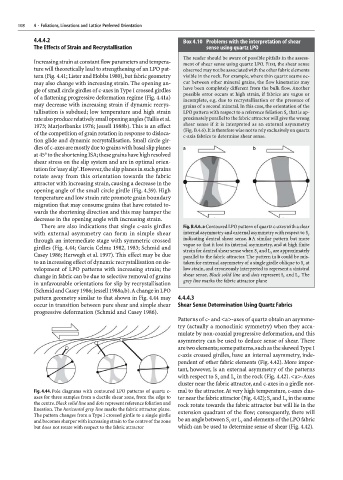

Fig. 4.44. Pole diagrams with contoured LPO patterns of quartz c- mal to the attractor. At very high temperature, c-axes clus-

axes for three samples from a ductile shear zone, from the edge to ter near the fabric attractor (Fig. 4.42); S and L in the same

r

r

the centre. Black solid line and dots represent reference foliation and rock rotate towards the fabric attractor but will lie in the

lineation. The horizontal grey line marks the fabric attractor plane.

The pattern changes from a Type I crossed girdle to a single girdle extension quadrant of the flow; consequently, there will

and becomes sharper with increasing strain to the centre of the zone be an angle between S or L and elements of the LPO fabric

r

r

but does not rotate with respect to the fabric attractor which can be used to determine sense of shear (Fig. 4.42).