Page 257 - Modeling of Chemical Kinetics and Reactor Design

P. 257

Industrial and Laboratory Reactors 227

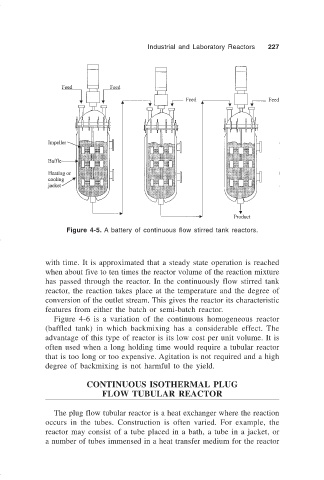

Figure 4-5. A battery of continuous flow stirred tank reactors.

with time. It is approximated that a steady state operation is reached

when about five to ten times the reactor volume of the reaction mixture

has passed through the reactor. In the continuously flow stirred tank

reactor, the reaction takes place at the temperature and the degree of

conversion of the outlet stream. This gives the reactor its characteristic

features from either the batch or semi-batch reactor.

Figure 4-6 is a variation of the continuous homogeneous reactor

(baffled tank) in which backmixing has a considerable effect. The

advantage of this type of reactor is its low cost per unit volume. It is

often used when a long holding time would require a tubular reactor

that is too long or too expensive. Agitation is not required and a high

degree of backmixing is not harmful to the yield.

CONTINUOUS ISOTHERMAL PLUG

FLOW TUBULAR REACTOR

The plug flow tubular reactor is a heat exchanger where the reaction

occurs in the tubes. Construction is often varied. For example, the

reactor may consist of a tube placed in a bath, a tube in a jacket, or

a number of tubes immensed in a heat transfer medium for the reactor