Page 262 - Modeling of Chemical Kinetics and Reactor Design

P. 262

232 Modeling of Chemical Kinetics and Reactor Design

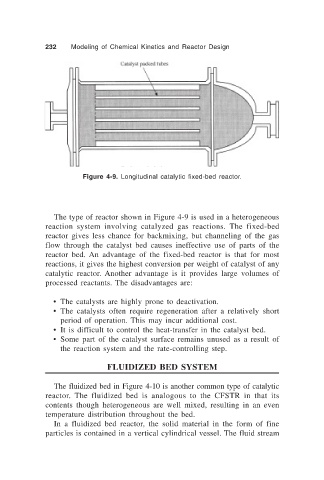

Figure 4-9. Longitudinal catalytic fixed-bed reactor.

The type of reactor shown in Figure 4-9 is used in a heterogeneous

reaction system involving catalyzed gas reactions. The fixed-bed

reactor gives less chance for backmixing, but channeling of the gas

flow through the catalyst bed causes ineffective use of parts of the

reactor bed. An advantage of the fixed-bed reactor is that for most

reactions, it gives the highest conversion per weight of catalyst of any

catalytic reactor. Another advantage is it provides large volumes of

processed reactants. The disadvantages are:

• The catalysts are highly prone to deactivation.

• The catalysts often require regeneration after a relatively short

period of operation. This may incur additional cost.

• It is difficult to control the heat-transfer in the catalyst bed.

• Some part of the catalyst surface remains unused as a result of

the reaction system and the rate-controlling step.

FLUIDIZED BED SYSTEM

The fluidized bed in Figure 4-10 is another common type of catalytic

reactor. The fluidized bed is analogous to the CFSTR in that its

contents though heterogeneous are well mixed, resulting in an even

temperature distribution throughout the bed.

In a fluidized bed reactor, the solid material in the form of fine

particles is contained in a vertical cylindrical vessel. The fluid stream