Page 267 - Modeling of Chemical Kinetics and Reactor Design

P. 267

Industrial and Laboratory Reactors 237

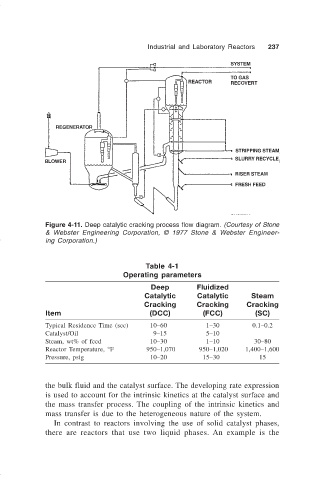

Figure 4-11. Deep catalytic cracking process flow diagram. (Courtesy of Stone

& Webster Engineering Corporation, © 1977 Stone & Webster Engineer-

ing Corporation.)

Table 4-1

Operating parameters

Deep Fluidized

Catalytic Catalytic Steam

Cracking Cracking Cracking

Item (DCC) (FCC) (SC)

Typical Residence Time (sec) 10–60 1–30 0.1–0.2

Catalyst/Oil 9–15 5–10

Steam, wt% of feed 10–30 1–10 30–80

Reactor Temperature, °F 950–1,070 950–1,020 1,400–1,600

Pressure, psig 10–20 15–30 15

the bulk fluid and the catalyst surface. The developing rate expression

is used to account for the intrinsic kinetics at the catalyst surface and

the mass transfer process. The coupling of the intrinsic kinetics and

mass transfer is due to the heterogeneous nature of the system.

In contrast to reactors involving the use of solid catalyst phases,

there are reactors that use two liquid phases. An example is the