Page 269 - Modeling of Chemical Kinetics and Reactor Design

P. 269

Industrial and Laboratory Reactors 239

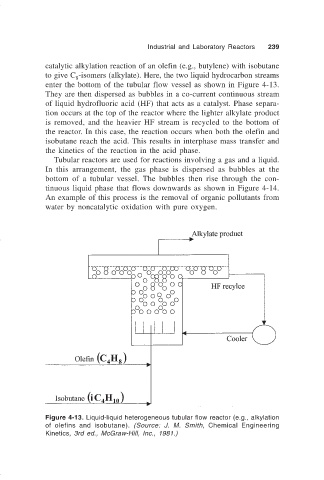

catalytic alkylation reaction of an olefin (e.g., butylene) with isobutane

to give C -isomers (alkylate). Here, the two liquid hydrocarbon streams

8

enter the bottom of the tubular flow vessel as shown in Figure 4-13.

They are then dispersed as bubbles in a co-current continuous stream

of liquid hydrofluoric acid (HF) that acts as a catalyst. Phase separa-

tion occurs at the top of the reactor where the lighter alkylate product

is removed, and the heavier HF stream is recycled to the bottom of

the reactor. In this case, the reaction occurs when both the olefin and

isobutane reach the acid. This results in interphase mass transfer and

the kinetics of the reaction in the acid phase.

Tubular reactors are used for reactions involving a gas and a liquid.

In this arrangement, the gas phase is dispersed as bubbles at the

bottom of a tubular vessel. The bubbles then rise through the con-

tinuous liquid phase that flows downwards as shown in Figure 4-14.

An example of this process is the removal of organic pollutants from

water by noncatalytic oxidation with pure oxygen.

Figure 4-13. Liquid-liquid heterogeneous tubular flow reactor (e.g., alkylation

of olefins and isobutane). (Source: J. M. Smith, Chemical Engineering

Kinetics, 3rd ed., McGraw-Hill, Inc., 1981.)