Page 270 - Modeling of Chemical Kinetics and Reactor Design

P. 270

240 Modeling of Chemical Kinetics and Reactor Design

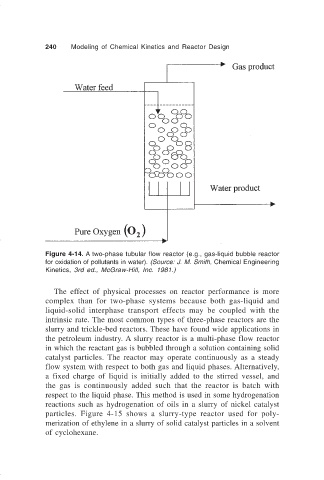

Figure 4-14. A two-phase tubular flow reactor (e.g., gas-liquid bubble reactor

for oxidation of pollutants in water). (Source: J. M. Smith, Chemical Engineering

Kinetics, 3rd ed., McGraw-Hill, Inc. 1981.)

The effect of physical processes on reactor performance is more

complex than for two-phase systems because both gas-liquid and

liquid-solid interphase transport effects may be coupled with the

intrinsic rate. The most common types of three-phase reactors are the

slurry and trickle-bed reactors. These have found wide applications in

the petroleum industry. A slurry reactor is a multi-phase flow reactor

in which the reactant gas is bubbled through a solution containing solid

catalyst particles. The reactor may operate continuously as a steady

flow system with respect to both gas and liquid phases. Alternatively,

a fixed charge of liquid is initially added to the stirred vessel, and

the gas is continuously added such that the reactor is batch with

respect to the liquid phase. This method is used in some hydrogenation

reactions such as hydrogenation of oils in a slurry of nickel catalyst

particles. Figure 4-15 shows a slurry-type reactor used for poly-

merization of ethylene in a slurry of solid catalyst particles in a solvent

of cyclohexane.