Page 273 - Modeling of Chemical Kinetics and Reactor Design

P. 273

Industrial and Laboratory Reactors 243

if the reaction is substantially exothermic, the evolved heat may cause

portions of the bed not to be wetted resulting in poor contacting of

catalyst and liquid. Satterfield [2], Ramanchandran, and Chaudhari [3]

have given detailed design procedures of three-phase catalytic reactors.

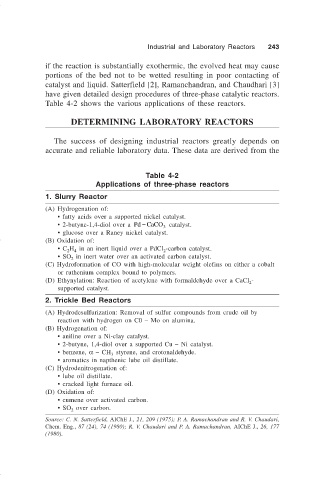

Table 4-2 shows the various applications of these reactors.

DETERMINING LABORATORY REACTORS

The success of designing industrial reactors greatly depends on

accurate and reliable laboratory data. These data are derived from the

Table 4-2

Applications of three-phase reactors

1. Slurry Reactor

(A) Hydrogenation of:

• fatty acids over a supported nickel catalyst.

• 2-butyne-1,4-diol over a Pd CaCO− 3 catalyst.

• glucose over a Raney nickel catalyst.

(B) Oxidation of:

• C H in an inert liquid over a PdCl -carbon catalyst.

4

2

2

• SO in inert water over an activated carbon catalyst.

2

(C) Hydroformation of CO with high-molecular weight olefins on either a cobalt

or ruthenium complex bound to polymers.

(D) Ethynylation: Reaction of acetylene with formaldehyde over a CaCl -

2

supported catalyst.

2. Trickle Bed Reactors

(A) Hydrodesulfurization: Removal of sulfur compounds from crude oil by

reaction with hydrogen on C0 – Mo on alumina.

(B) Hydrogenation of:

• aniline over a Ni-clay catalyst.

• 2-butyne, 1,4-diol over a supported Cu – Ni catalyst.

• benzene, α – CH styrene, and crotonaldehyde.

3

• aromatics in napthenic lube oil distillate.

(C) Hydrodenitrogenation of:

• lube oil distillate.

• cracked light furnace oil.

(D) Oxidation of:

• cumene over activated carbon.

• SO over carbon.

2

Source: C. N. Satterfield, AIChE J., 21, 209 (1975); P. A. Ramachandran and R. V. Chaudari,

Chem. Eng., 87 (24), 74 (1980); R. V. Chaudari and P. A. Ramachandran, AIChE J., 26, 177

(1980).