Page 277 - Modeling of Chemical Kinetics and Reactor Design

P. 277

Industrial and Laboratory Reactors 247

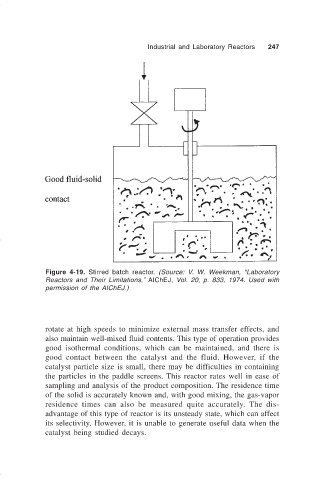

Figure 4-19. Stirred batch reactor. (Source: V. W. Weekman, “Laboratory

Reactors and Their Limitations,” AIChEJ, Vol. 20, p. 833, 1974. Used with

permission of the AIChEJ.)

rotate at high speeds to minimize external mass transfer effects, and

also maintain well-mixed fluid contents. This type of operation provides

good isothermal conditions, which can be maintained, and there is

good contact between the catalyst and the fluid. However, if the

catalyst particle size is small, there may be difficulties in containing

the particles in the paddle screens. This reactor rates well in ease of

sampling and analysis of the product composition. The residence time

of the solid is accurately known and, with good mixing, the gas-vapor

residence times can also be measured quite accurately. The dis-

advantage of this type of reactor is its unsteady state, which can affect

its selectivity. However, it is unable to generate useful data when the

catalyst being studied decays.