Page 279 - Modeling of Chemical Kinetics and Reactor Design

P. 279

Industrial and Laboratory Reactors 249

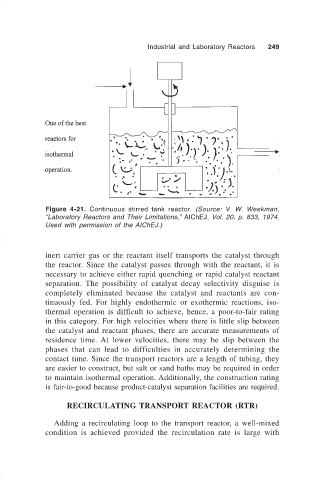

Figure 4-21. Continuous stirred tank reactor. (Source: V. W. Weekman,

“Laboratory Reactors and Their Limitations,” AIChEJ, Vol. 20, p. 833, 1974.

Used with permission of the AIChEJ.)

inert carrier gas or the reactant itself transports the catalyst through

the reactor. Since the catalyst passes through with the reactant, it is

necessary to achieve either rapid quenching or rapid catalyst reactant

separation. The possibility of catalyst decay selectivity disguise is

completely eliminated because the catalyst and reactants are con-

tinuously fed. For highly endothermic or exothermic reactions, iso-

thermal operation is difficult to achieve, hence, a poor-to-fair rating

in this category. For high velocities where there is little slip between

the catalyst and reactant phases, there are accurate measurements of

residence time. At lower velocities, there may be slip between the

phases that can lead to difficulties in accurately determining the

contact time. Since the transport reactors are a length of tubing, they

are easier to construct, but salt or sand baths may be required in order

to maintain isothermal operation. Additionally, the construction rating

is fair-to-good because product-catalyst separation facilities are required.

RECIRCULATING TRANSPORT REACTOR (RTR)

Adding a recirculating loop to the transport reactor, a well-mixed

condition is achieved provided the recirculation rate is large with