Page 271 - Modeling of Chemical Kinetics and Reactor Design

P. 271

Industrial and Laboratory Reactors 241

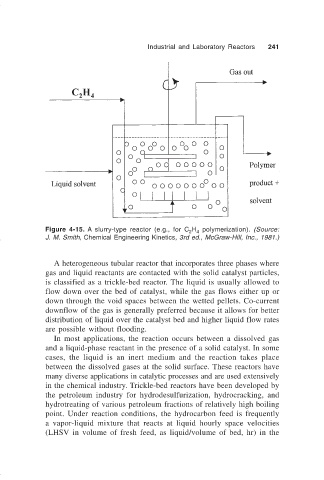

Figure 4-15. A slurry-type reactor (e.g., for C H polymerization). (Source:

2 4

J. M. Smith, Chemical Engineering Kinetics, 3rd ed., McGraw-Hill, Inc., 1981.)

A heterogeneous tubular reactor that incorporates three phases where

gas and liquid reactants are contacted with the solid catalyst particles,

is classified as a trickle-bed reactor. The liquid is usually allowed to

flow down over the bed of catalyst, while the gas flows either up or

down through the void spaces between the wetted pellets. Co-current

downflow of the gas is generally preferred because it allows for better

distribution of liquid over the catalyst bed and higher liquid flow rates

are possible without flooding.

In most applications, the reaction occurs between a dissolved gas

and a liquid-phase reactant in the presence of a solid catalyst. In some

cases, the liquid is an inert medium and the reaction takes place

between the dissolved gases at the solid surface. These reactors have

many diverse applications in catalytic processes and are used extensively

in the chemical industry. Trickle-bed reactors have been developed by

the petroleum industry for hydrodesulfurization, hydrocracking, and

hydrotreating of various petroleum fractions of relatively high boiling

point. Under reaction conditions, the hydrocarbon feed is frequently

a vapor-liquid mixture that reacts at liquid hourly space velocities

(LHSV in volume of fresh feed, as liquid/volume of bed, hr) in the