Page 231 - Modelling in Transport Phenomena A Conceptual Approach

P. 231

7.6. DESIGN OF A SPRAY TOWER 21 1

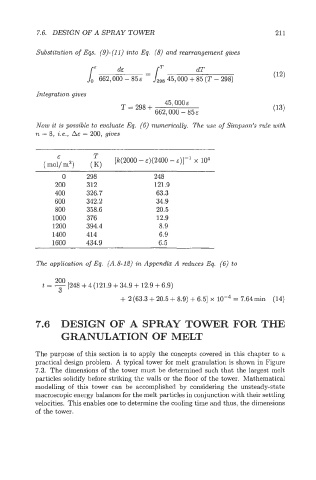

Substitution of Eqs. (9)-(11) into Eq. (8) and rearrangement gives

Ck dT

Integration gives

T = 298 + 45,000 E (13)

662,000 - 85 E

Now it is possible to evaluate Eq. (6) numerically. The use of Simpson's rule with

n = 8, i.e., Ae = 200, gives

E: [k(2000 - e)(2400 - E)]-' x lo4

(mol/m3) (K)

0 298 248

200 312 121.9

400 326.7 63.3

600 342.2 34.9

800 358.6 20.5

1000 376 12.9

1200 394.4 8.9

1400 414 6.9

1600 434.9 6.5

The application of Eq. (A.8-12) in Appendix A duces Eq. (6) to

200

t = - [248 + 4 (121.9 + 34.9 + 12.9 + 6.9)

3

+ 2 (63.3 + 20.5 + 8.9) + 6.51 x = 7.64min (14)

7.6 DESIGN OF A SPRAY TOWR FOR THE

GRANULATION OF MELT

The purpose of this section is to apply the concepts covered in this chapter to a

practical design problem. A typical tower for melt granulation is shown in Figure

7.3. The dimensions of the tower must be determined such that the largest melt

particles solidify before striking the walls or the floor of the tower. Mathematical

modelling of this tower can be accomplished by considering the unsteady-state

macroscopic energy balances for the melt particles in conjunction with their settling

velocities. This enables one to determine the cooling time and thus, the dimensions

of the tower.