Page 117 - Modular design for machine tools

P. 117

Engineering Guides and Future Perspectives of Modular Design 79

Turret head available

`for rotating tool

Headstock with

index function

Turret head for

stationary tool

Bye-headstock

Tailstock

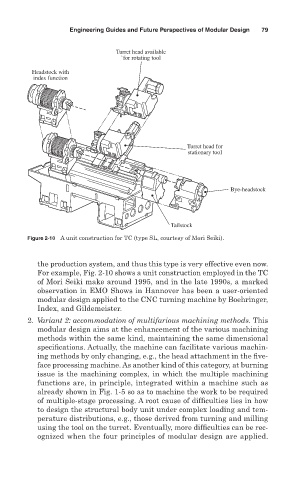

Figure 2-10 A unit construction for TC (type SL, courtesy of Mori Seiki).

the production system, and thus this type is very effective even now.

For example, Fig. 2-10 shows a unit construction employed in the TC

of Mori Seiki make around 1995, and in the late 1990s, a marked

observation in EMO Shows in Hannover has been a user- oriented

modular design applied to the CNC turning machine by Boehringer,

Index, and Gildemeister.

2. Variant 2: accommodation of multifarious machining methods. This

modular design aims at the enhancement of the various machining

methods within the same kind, maintaining the same dimensional

specifications. Actually, the machine can facilitate various machin-

ing methods by only changing, e.g., the head attachment in the five-

face processing machine. As another kind of this category, at burning

issue is the machining complex, in which the multiple machining

functions are, in principle, integrated within a machine such as

already shown in Fig. 1-5 so as to machine the work to be required

of multiple-stage processing. A root cause of difficulties lies in how

to design the structural body unit under complex loading and tem-

perature distributions, e.g., those derived from turning and milling

using the tool on the turret. Eventually, more difficulties can be rec-

ognized when the four principles of modular design are applied.