Page 113 - Modular design for machine tools

P. 113

76 Modular Design Guide and Machine Tools Description

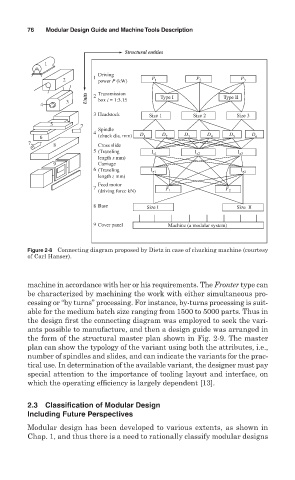

Structural entities

1

Driving

1

2 power P (kW) P 1 P 2 P 3

Units 2 Transmission Type I Type II

3 box i = 1:3.15

4

3 Headstock Size 1 Size 2 Size 3

5

7

Spindle

4 D D D D D D

6 (chuck dia. mm) 1 2 3 4 5 6

7 8 Cross slide

5 (Traveling l x1 l x2 l x3

length x mm)

9 Carriage

6 (Traveling l z1 l z2

length z mm)

Feed motor

7

(driving force kN) F 1 F 2

8 Base Size I Size II

9 Cover panel Machine (a modular system)

Figure 2-8 Connecting diagram proposed by Dietz in case of chucking machine (courtesy

of Carl Hanser).

machine in accordance with her or his requirements. The Fronter type can

be characterized by machining the work with either simultaneous pro-

cessing or “by turns” processing. For instance, by-turns processing is suit-

able for the medium batch size ranging from 1500 to 5000 parts. Thus in

the design first the connecting diagram was employed to seek the vari-

ants possible to manufacture, and then a design guide was arranged in

the form of the structural master plan shown in Fig. 2-9. The master

plan can show the typology of the variant using both the attributes, i.e.,

number of spindles and slides, and can indicate the variants for the prac-

tical use. In determination of the available variant, the designer must pay

special attention to the importance of tooling layout and interface, on

which the operating efficiency is largely dependent [13].

2.3 Classification of Modular Design

Including Future Perspectives

Modular design has been developed to various extents, as shown in

Chap. 1, and thus there is a need to rationally classify modular designs