Page 108 - Modular design for machine tools

P. 108

72 Modular Design Guide and Machine Tools Description

2.2 Effective Tools and Methodology

for Modular Design

Admitting that the principles of both separation and unification are

facilitated by the trial-and-error method employed by learned and

mature designers, an extremely crucial problem in the modular design

is how to execute the principle of adaptation. As can be readily seen from

Sec. 2.1 and will be stated in Chaps. 3 and 4, some computer- aided

methodologies are now available with the assistance of the machine

tool description. Although the computer- aided methodology is very pow-

erful, the manually based method is, in certain cases, very effective and

aids in the understanding of the essential features of modular design.

Thus in the following discussion, some manually based methods of old

are reproduced.

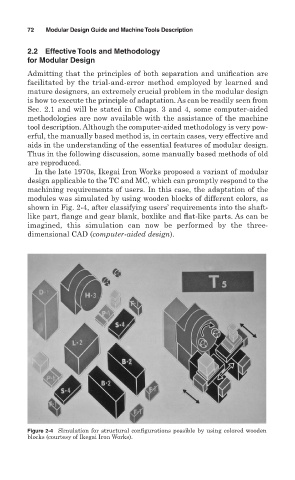

In the late 1970s, Ikegai Iron Works proposed a variant of modular

design applicable to the TC and MC, which can promptly respond to the

machining requirements of users. In this case, the adaptation of the

modules was simulated by using wooden blocks of different colors, as

shown in Fig. 2-4, after classifying users’ requirements into the shaft-

like part, flange and gear blank, boxlike and flat-like parts. As can be

imagined, this simulation can now be performed by the three-

dimensional CAD (computer-aided design).

Figure 2-4 Simulation for structural configurations possible by using colored wooden

blocks (courtesy of Ikegai Iron Works).