Page 104 - Modular design for machine tools

P. 104

68 Modular Design Guide and Machine Tools Description

Principle of connection. In modular design, the machine tool as a whole

has a considerable number of joints, and thus the principle of connec-

tion should be interpreted as follows.

When modular design is employed, the jointing method and joint surface

should be unified at least or standardized in the most preferable case while

maintaining allowable assembly accuracy and acceptable joint stiffness under

the repeated use of the module.

In this principle, a basic necessity is to consider the mutual effect of

the jointing accuracy and joint stiffness. In addition, it is preferable

that the reference surface be separated from the bearing surface for

loading, to realize the allowable magnitudes in both assembly accuracy

and joint stiffness.

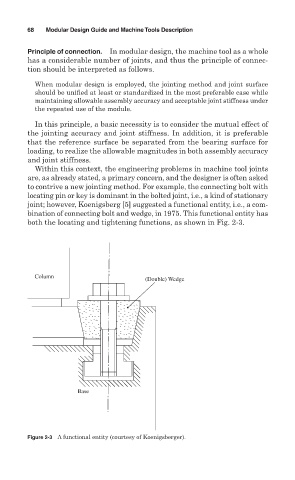

Within this context, the engineering problems in machine tool joints

are, as already stated, a primary concern, and the designer is often asked

to contrive a new jointing method. For example, the connecting bolt with

locating pin or key is dominant in the bolted joint, i.e., a kind of stationary

joint; however, Koenigsberg [5] suggested a functional entity, i.e., a com-

bination of connecting bolt and wedge, in 1975. This functional entity has

both the locating and tightening functions, as shown in Fig. 2- 3.

Column

(Double) Wedge

Base

Figure 2-3 A functional entity (courtesy of Koenigsberger).