Page 109 - Modular design for machine tools

P. 109

Engineering Guides and Future Perspectives of Modular Design 73

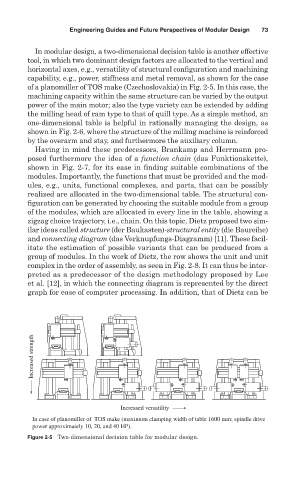

In modular design, a two-dimensional decision table is another effective

tool, in which two dominant design factors are allocated to the vertical and

horizontal axes, e.g., versatility of structural configuration and machining

capability, e.g., power, stiffness and metal removal, as shown for the case

of a planomiller of TOS make (Czechoslovakia) in Fig. 2-5. In this case, the

machining capacity within the same structure can be varied by the output

power of the main motor; also the type variety can be extended by adding

the milling head of ram type to that of quill type. As a simple method, an

one-dimensional table is helpful in rationally managing the design, as

shown in Fig. 2-6, where the structure of the milling machine is reinforced

by the overarm and stay, and furthermore the auxiliary column.

Having in mind these predecessors, Brankamp and Herrmann pro-

posed furthermore the idea of a function chain (das Funktionskette),

shown in Fig. 2-7, for its ease in finding suitable combinations of the

modules. Importantly, the functions that must be provided and the mod-

ules, e.g., units, functional complexes, and parts, that can be possibly

realized are allocated in the two-dimensional table. The structural con-

figuration can be generated by choosing the suitable module from a group

of the modules, which are allocated in every line in the table, showing a

zigzag choice trajectory, i.e., chain. On this topic, Dietz proposed two sim-

ilar ideas called structure (der Baukasten)-structural entity (die Baureihe)

and connecting diagram (das Verknupfungs- Diagramm) [11]. These facil-

itate the estimation of possible variants that can be produced from a

group of modules. In the work of Dietz, the row shows the unit and unit

complex in the order of assembly, as seen in Fig. 2-8. It can thus be inter-

preted as a predecessor of the design methodology proposed by Lee

et al. [12], in which the connecting diagram is represented by the direct

graph for ease of computer processing. In addition, that of Dietz can be

Increased strength

Increased versatility

In case of planomiller of TOS make (maximum clamping width of table 1600 mm; spindle drive

power approximately 10, 20, and 40 HP).

Figure 2-5 Two- dimensional decision table for modular design.