Page 30 - Modular design for machine tools

P. 30

4 Modular Design Guide and Machine Tools Description

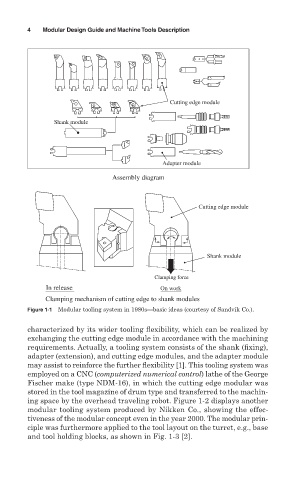

Cutting edge module

Shank module

Adapter module

Assembly diagram

Cutting edge module

Shank module

Clamping force

In release On work

Clamping mechanism of cutting edge to shank modules

Figure 1-1 Modular tooling system in 1980s—basic ideas (courtesy of Sandvik Co.).

characterized by its wider tooling flexibility, which can be realized by

exchanging the cutting edge module in accordance with the machining

requirements. Actually, a tooling system consists of the shank (fixing),

adapter (extension), and cutting edge modules, and the adapter module

may assist to reinforce the further flexibility [1]. This tooling system was

employed on a CNC (computerized numerical control) lathe of the George

Fischer make (type NDM-16), in which the cutting edge modular was

stored in the tool magazine of drum type and transferred to the machin-

ing space by the overhead traveling robot. Figure 1-2 displays another

modular tooling system produced by Nikken Co., showing the effec-

tiveness of the modular concept even in the year 2000. The modular prin-

ciple was furthermore applied to the tool layout on the turret, e.g., base

and tool holding blocks, as shown in Fig. 1-3 [2].