Page 33 - Modular design for machine tools

P. 33

Basic Knowledge: What Is the Modular Design? 7

(flexible transfer line), to a five-face processing machine. In this case, the

leading modules are the column, base, rotary table, tool magazine, main

motor, and so on. This machine appears to be a typical predecessor of

current five-face processing machines.

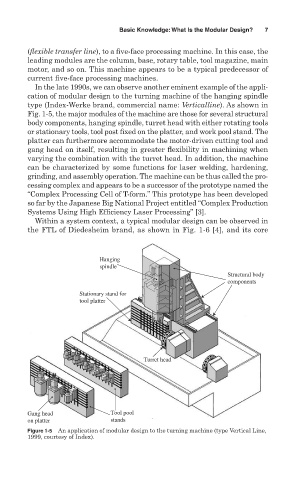

In the late 1990s, we can observe another eminent example of the appli-

cation of modular design to the turning machine of the hanging spindle

type (Index-Werke brand, commercial name: Verticalline). As shown in

Fig. 1-5, the major modules of the machine are those for several structural

body components, hanging spindle, turret head with either rotating tools

or stationary tools, tool post fixed on the platter, and work pool stand. The

platter can furthermore accommodate the motor-driven cutting tool and

gang head on itself, resulting in greater flexibility in machining when

varying the combination with the turret head. In addition, the machine

can be characterized by some functions for laser welding, hardening,

grinding, and assembly operation. The machine can be thus called the pro-

cessing complex and appears to be a successor of the prototype named the

“Complex Processing Cell of T-form.” This prototype has been developed

so far by the Japanese Big National Project entitled “Complex Production

Systems Using High Efficiency Laser Processing” [3].

Within a system context, a typical modular design can be observed in

the FTL of Diedesheim brand, as shown in Fig. 1-6 [4], and its core

Hanging

spindle

Structural body

components

Stationary stand for

tool platter

Turret head

Gang head Tool pool

on platter stands

Figure 1-5 An application of modular design to the turning machine (type Vertical Line,

1999, courtesy of Index).