Page 10 - New Trends In Coal Conversion

P. 10

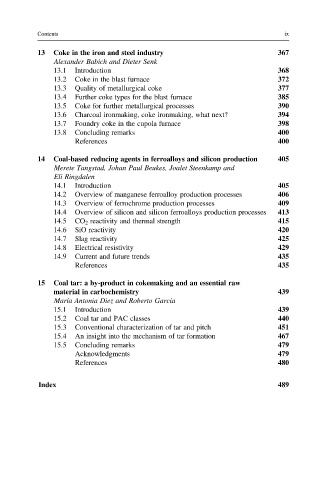

Contents ix

13 Coke in the iron and steel industry 367

Alexander Babich and Dieter Senk

13.1 Introduction 368

13.2 Coke in the blast furnace 372

13.3 Quality of metallurgical coke 377

13.4 Further coke types for the blast furnace 385

13.5 Coke for further metallurgical processes 390

13.6 Charcoal ironmaking, coke ironmaking, what next? 394

13.7 Foundry coke in the cupola furnace 398

13.8 Concluding remarks 400

References 400

14 Coal-based reducing agents in ferroalloys and silicon production 405

Merete Tangstad, Johan Paul Beukes, Joalet Steenkamp and

Eli Ringdalen

14.1 Introduction 405

14.2 Overview of manganese ferroalloy production processes 406

14.3 Overview of ferrochrome production processes 409

14.4 Overview of silicon and silicon ferroalloys production processes 413

14.5 CO 2 reactivity and thermal strength 415

14.6 SiO reactivity 420

14.7 Slag reactivity 425

14.8 Electrical resistivity 429

14.9 Current and future trends 435

References 435

15 Coal tar: a by-product in cokemaking and an essential raw

material in carbochemistry 439

María Antonia Diez and Roberto Garcia

15.1 Introduction 439

15.2 Coal tar and PAC classes 440

15.3 Conventional characterization of tar and pitch 451

15.4 An insight into the mechanism of tar formation 467

15.5 Concluding remarks 479

Acknowledgments 479

References 480

Index 489