Page 158 - New Trends In Coal Conversion

P. 158

Coal and biomass cofiring: fundamentals and future trends 121

dictates the amount of air required for combustion (stoichiometry), and if less air is

required, less nonreacting components of the air (mostly N 2 ) need to be heated to

the flame temperature (Madanayake et al., 2017). The higher O content of biomass

means that less air is required for combustion, compared with typical hydrocarbon

fuels (Jenkins et al., 1998). Hence, biomass fuels have the potential to achieve higher

combustion efficiencies compared with other hydrocarbon fuels. The higher volatility

of biomass improves its reactivity and ignition characteristics compared with coal, and

this usually results in a lower activation energy barrier to devolatilization and oxidation

(Agbor et al., 2014).

5.3 Coal and biomass cofiring technologies

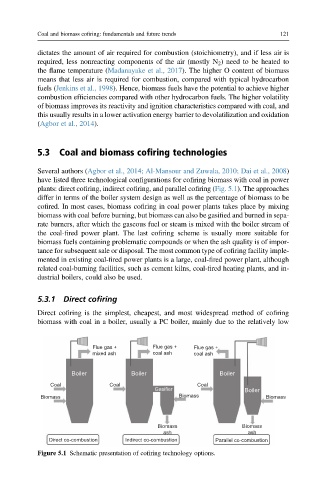

Several authors (Agbor et al., 2014; Al-Mansour and Zuwala, 2010; Dai et al., 2008)

have listed three technological configurations for cofiring biomass with coal in power

plants: direct cofiring, indirect cofiring, and parallel cofiring (Fig. 5.1). The approaches

differ in terms of the boiler system design as well as the percentage of biomass to be

cofired. In most cases, biomass cofiring in coal power plants takes place by mixing

biomass with coal before burning, but biomass can also be gasified and burned in sepa-

rate burners, after which the gaseous fuel or steam is mixed with the boiler stream of

the coal-fired power plant. The last cofiring scheme is usually more suitable for

biomass fuels containing problematic compounds or when the ash quality is of impor-

tance for subsequent sale or disposal. The most common type of cofiring facility imple-

mented in existing coal-fired power plants is a large, coal-fired power plant, although

related coal-burning facilities, such as cement kilns, coal-fired heating plants, and in-

dustrial boilers, could also be used.

5.3.1 Direct cofiring

Direct cofiring is the simplest, cheapest, and most widespread method of cofiring

biomass with coal in a boiler, usually a PC boiler, mainly due to the relatively low

Flue gas + Flue gas + Flue gas +

mixed ash coal ash coal ash

Boiler Boiler Boiler

Coal Coal Coal

Gasifier Boiler

Biomass Biomass Biomass

Biomass Biomass

ash ash

Direct co-combustion Indirect co-combustion Parallel co-combustion

Figure 5.1 Schematic presentation of cofiring technology options.