Page 152 - New Trends in Eco efficient and Recycled Concrete

P. 152

126 New Trends in Eco-efficient and Recycled Concrete

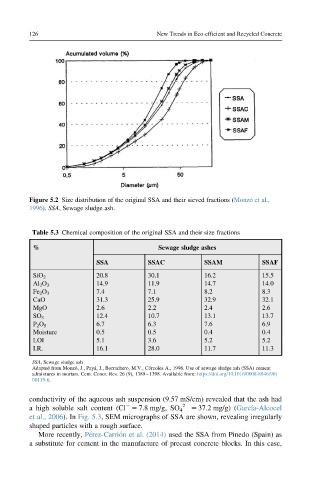

Figure 5.2 Size distribution of the original SSA and their sieved fractions (Monzo ´ et al.,

1996). SSA, Sewage sludge ash.

Table 5.3 Chemical composition of the original SSA and their size fractions

% Sewage sludge ashes

SSA SSAC SSAM SSAF

20.8 30.1 16.2 15.5

SiO 2

14.9 11.9 14.7 14.0

Al 2 O 3

7.4 7.1 8.2 8.3

Fe 2 O 3

CaO 31.3 25.9 32.9 32.1

MgO 2.6 2.2 2.4 2.6

12.4 10.7 13.1 13.7

SO 3

6.7 6.3 7.6 6.9

P 2 O 5

Moisture 0.5 0.5 0.4 0.4

LOI 5.1 3.6 5.2 5.2

I.R. 16.1 28.0 11.7 11.3

SSA, Sewage sludge ash

Adapted from Monzo ´, J., Paya ´, J., Borrachero, M.V., Co ´rcoles A., 1996. Use of sewage sludge ash (SSA) cement

admixtures in mortars. Cem. Concr. Res. 26 (9), 1389 1398. Available from: https://doi.org/10.1016/0008-8846(96)

00119-6.

conductivity of the aqueous ash suspension (9.57 mS/cm) revealed that the ash had

2 22

a high soluble salt content (Cl 5 7.8 mg/g, SO 4 5 37.2 mg/g) (Garcı ´a-Alcocel

et al., 2006). In Fig. 5.3, SEM micrographs of SSA are shown, revealing irregularly

shaped particles with a rough surface.

More recently, Pe ´rez-Carrio ´n et al. (2014) used the SSA from Pinedo (Spain) as

a substitute for cement in the manufacture of precast concrete blocks. In this case,