Page 182 - New Trends in Eco efficient and Recycled Concrete

P. 182

154 New Trends in Eco-efficient and Recycled Concrete

450 30%

Glass bottle Other glass Recovery rate

400

25%

350

Waste glass tonnes per day 300 20% Recovery rate

250

15%

200

10%

150

100

5%

50

0 0%

2015 2014 2013 2012 2011 2010 2009 2008 2007 2006 2005 2004 2003 2002 2001 2000 1999 1998 1997

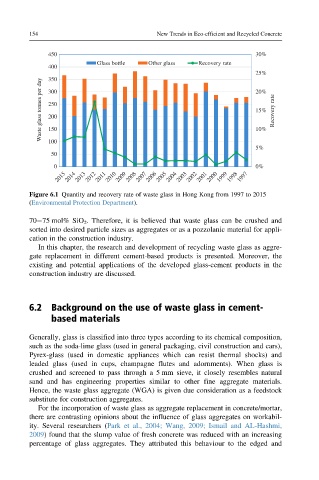

Figure 6.1 Quantity and recovery rate of waste glass in Hong Kong from 1997 to 2015

(Environmental Protection Department).

70 75 mol% SiO 2 . Therefore, it is believed that waste glass can be crushed and

sorted into desired particle sizes as aggregates or as a pozzolanic material for appli-

cation in the construction industry.

In this chapter, the research and development of recycling waste glass as aggre-

gate replacement in different cement-based products is presented. Moreover, the

existing and potential applications of the developed glass-cement products in the

construction industry are discussed.

6.2 Background on the use of waste glass in cement-

based materials

Generally, glass is classified into three types according to its chemical composition,

such as the soda-lime glass (used in general packaging, civil construction and cars),

Pyrex-glass (used in domestic appliances which can resist thermal shocks) and

leaded glass (used in cups, champagne flutes and adornments). When glass is

crushed and screened to pass through a 5 mm sieve, it closely resembles natural

sand and has engineering properties similar to other fine aggregate materials.

Hence, the waste glass aggregate (WGA) is given due consideration as a feedstock

substitute for construction aggregates.

For the incorporation of waste glass as aggregate replacement in concrete/mortar,

there are contrasting opinions about the influence of glass aggregates on workabil-

ity. Several researchers (Park et al., 2004; Wang, 2009; Ismail and AL-Hashmi,

2009) found that the slump value of fresh concrete was reduced with an increasing

percentage of glass aggregates. They attributed this behaviour to the edged and