Page 26 - New Trends in Eco efficient and Recycled Concrete

P. 26

Construction and demolition waste 3

A different combination of these processes can be seen in different plants; the

implementation or removal of those steps depends on the quality of the input CDW.

If the original CDW has high quality, lower quantity of treatments may be applied

to obtain adequate RA. In this way, if selected concrete blocks with lower contami-

nation content are used as input CDW, it is possible that, apart from the crushing

and screening stages, only an additional electromagnetic separation would be

required to produce high-quality recycled concrete aggregates (RCAs). On the other

hand, in the case of low-quality CDW with different types of components, a greater

complexity of treatments would be required to obtain suitable RA, including pre-

screening, air separation and manual separation. Under these circumstances, a

mixed RA (MRA) would be expected to result from this process.

1.2.1 Treatment processes for construction and demolition

waste

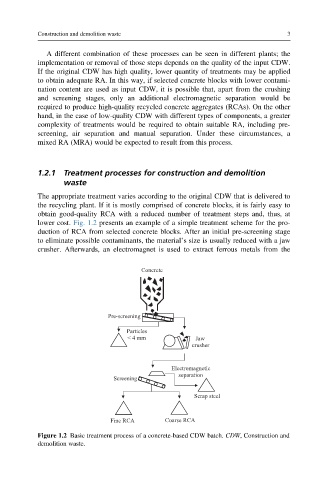

The appropriate treatment varies according to the original CDW that is delivered to

the recycling plant. If it is mostly comprised of concrete blocks, it is fairly easy to

obtain good-quality RCA with a reduced number of treatment steps and, thus, at

lower cost. Fig. 1.2 presents an example of a simple treatment scheme for the pro-

duction of RCA from selected concrete blocks. After an initial pre-screening stage

to eliminate possible contaminants, the material’s size is usually reduced with a jaw

crusher. Afterwards, an electromagnet is used to extract ferrous metals from the

Concrete

Pre-screening

Particles

< 4 mm Jaw

crusher

Electromagnetic

separation

Screening

Scrap steel

Fine RCA Coarse RCA

Figure 1.2 Basic treatment process of a concrete-based CDW batch. CDW, Construction and

demolition waste.