Page 27 - New Trends in Eco efficient and Recycled Concrete

P. 27

4 New Trends in Eco-efficient and Recycled Concrete

fragmented material, followed by a final screening stage to obtain an appropriate

particle size distribution in coarse, fine or all-in RCA.

On the other hand, severely heterogeneous batches will require a larger number

of treatment steps to produce a RA with sufficient quality for concrete, resulting in

a more expensive process. After the initial pre-screening, which probably removes

a higher number of contaminants when compared with the previous type of CDW,

the material goes through a jaw crusher followed by an electromagnetic separation

stage. The second screening stage may also contain an air-sifting process to remove

the likely presence of lightweight particles (e.g., gypsum).

Other steps may also be implemented depending on the initial batch’s level of

contamination and intended output quality. For example, secondary and tertiary

crushing stages may be applied to coarse particles. This results in fragments with a

rounder shape and with lower adhered mortar content. An Eddy-current separator

may also be part of the process to remove non-ferrous metals from the CDW after

going through the electromagnetic separator.

1.2.2 Main types of recycled aggregates from construction and

demolition waste

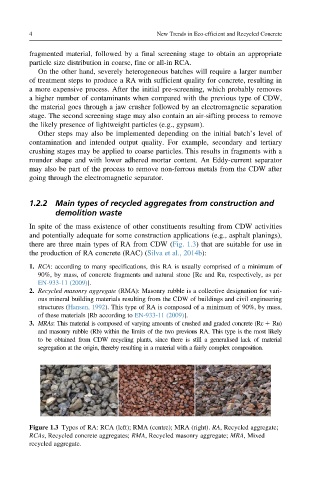

In spite of the mass existence of other constituents resulting from CDW activities

and potentially adequate for some construction applications (e.g., asphalt planings),

there are three main types of RA from CDW (Fig. 1.3) that are suitable for use in

the production of RA concrete (RAC) (Silva et al., 2014b):

1. RCA: according to many specifications, this RA is usually comprised of a minimum of

90%, by mass, of concrete fragments and natural stone [Rc and Ru, respectively, as per

EN-933-11 (2009)].

2. Recycled masonry aggregate (RMA): Masonry rubble is a collective designation for vari-

ous mineral building materials resulting from the CDW of buildings and civil engineering

structures (Hansen, 1992). This type of RA is composed of a minimum of 90%, by mass,

of these materials [Rb according to EN-933-11 (2009)].

3. MRAs: This material is composed of varying amounts of crushed and graded concrete (Rc 1 Ru)

and masonry rubble (Rb) within the limits of the two previous RA. This type is the most likely

to be obtained from CDW recycling plants, since there is still a generalised lack of material

segregation at the origin, thereby resulting in a material with a fairly complex composition.

Figure 1.3 Types of RA: RCA (left); RMA (centre); MRA (right). RA, Recycled aggregate;

RCAs, Recycled concrete aggregates; RMA, Recycled masonry aggregate; MRA, Mixed

recycled aggregate.