Page 385 - New Trends in Eco efficient and Recycled Concrete

P. 385

340 New Trends in Eco-efficient and Recycled Concrete

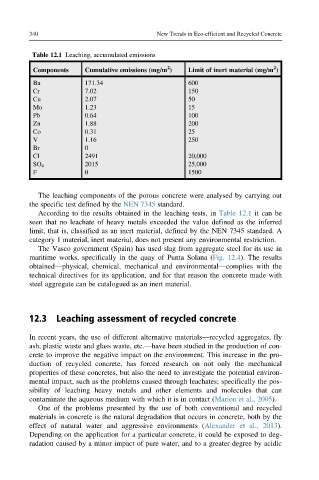

Table 12.1 Leaching, accumulated emissions

2

2

Components Cumulative emissions (mg/m ) Limit of inert material (mg/m )

Ba 171.34 600

Cr 7.02 150

Cu 2.07 50

Mo 1.23 15

Pb 0.64 100

Zn 1.88 200

Co 0.31 25

V 1.16 250

Br 0

Cl 2491 20,000

2015 25,000

SO 4

F 0 1500

The leaching components of the porous concrete were analysed by carrying out

the specific test defined by the NEN 7345 standard.

According to the results obtained in the leaching tests, in Table 12.1 it can be

seen that no leachate of heavy metals exceeded the value defined as the inferred

limit, that is, classified as an inert material, defined by the NEN 7345 standard. A

category 1 material, inert material, does not present any environmental restriction.

The Vasco government (Spain) has used slag from aggregate steel for its use in

maritime works, specifically in the quay of Punta Solana (Fig. 12.4). The results

obtained—physical, chemical, mechanical and environmental—complies with the

technical directives for its application, and for that reason the concrete made with

steel aggregate can be catalogued as an inert material.

12.3 Leaching assessment of recycled concrete

In recent years, the use of different alternative materials—recycled aggregates, fly

ash, plastic waste and glass waste, etc.—have been studied in the production of con-

crete to improve the negative impact on the environment. This increase in the pro-

duction of recycled concrete, has forced research on not only the mechanical

properties of these concretes, but also the need to investigate the potential environ-

mental impact, such as the problems caused through leachates; specifically the pos-

sibility of leaching heavy metals and other elements and molecules that can

contaminate the aqueous medium with which it is in contact (Marion et al., 2005).

One of the problems presented by the use of both conventional and recycled

materials in concrete is the natural degradation that occurs in concrete, both by the

effect of natural water and aggressive environments (Alexander et al., 2013).

Depending on the application for a particular concrete, it could be exposed to deg-

radation caused by a minor impact of pure water, and to a greater degree by acidic