Page 390 - New Trends in Eco efficient and Recycled Concrete

P. 390

Leaching issues in recycled aggregate concrete 345

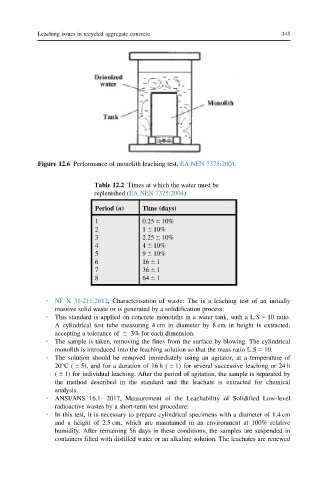

Figure 12.6 Performance of monolith leaching test, EA NEN 7375:2004.

Table 12.2 Times at which the water must be

replenished (EA NEN 7375:2004)

Period (n) Time (days)

1 0.25 6 10%

2 1 6 10%

3 2.25 6 10%

4 4 6 10%

5 9 6 10%

6 16 6 1

7 36 6 1

8 64 6 1

NF X 31-211:2012, Characterisation of waste: The is a leaching test of an initially

massive solid waste or is generated by a solidification process:

This standard is applied on concrete monoliths in a water tank, with a L:S 5 10 ratio.

A cylindrical test tube measuring 4 cm in diameter by 8 cm in height is extracted,

accepting a tolerance of 6 3% for each dimension.

The sample is taken, removing the fines from the surface by blowing. The cylindrical

monolith is introduced into the leaching solution so that the mass ratio L:S 5 10.

The solution should be removed immediately using an agitator, at a temperature of

20 C( 6 5), and for a duration of 16 h ( 6 1) for several successive leaching or 24 h

( 6 1) for individual leaching. After the period of agitation, the sample is separated by

the method described in the standard and the leachate is extracted for chemical

analysis.

ANSI/ANS 16.1- 2017, Measurement of the Leachability of Solidified Low-level

radioactive wastes by a short-term test procedure:

In this test, it is necessary to prepare cylindrical specimens with a diameter of 1.4 cm

and a height of 2.5 cm, which are maintained in an environment at 100% relative

humidity. After remaining 56 days in these conditions, the samples are suspended in

containers filled with distilled water or an alkaline solution. The leachates are renewed