Page 520 - New Trends in Eco efficient and Recycled Concrete

P. 520

468 New Trends in Eco-efficient and Recycled Concrete

Table 15.3 Aggregate properties

Type of aggregate

Parameter Gravel Unglazed ceramic Glazed ceramic

Diameter (mm) 12.5 12.5 12.5

Shape Circular Circular Circular

Elastic modulus (GPa) 109.7 99.9 88.40

Poisson’s ratio 0.2 0.2 0.2

80.00

Unglazed ceramic aggregate Glazed ceramic aggregate Gravel

70.00

3

2

= –0.011x + 0.7687x – 16.659x + 136.03

gravel

y

R 2 = 0.9943

60.00 3 2

Elastic modulus (GPa) 40.00 y glazed ceramic aggregate = –0.0063x + 0.4721x – 11.011x + 105.13

50.00

R 2

= 0.9956

30.00

20.00

3

2

= –0.0052x + 0.3511x – 7.4x + 75.4

unglazed ceramic aggregate

y

2

R = 0.9849

10.00

Cementitous

ITZ

matrix

Aggregate

0.00 (paste)

0 5 10 15 20 25 30 35

Distance from the interface (μ μm)

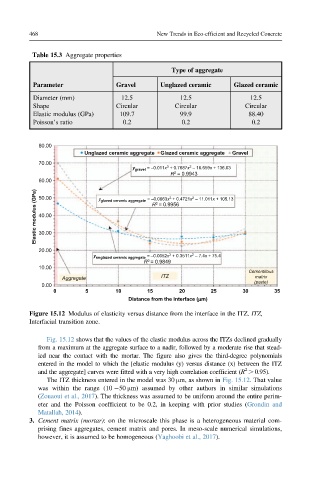

Figure 15.12 Modulus of elasticity versus distance from the interface in the ITZ. ITZ,

Interfacial transition zone.

Fig. 15.12 shows that the values of the elastic modulus across the ITZs declined gradually

from a maximum at the aggregate surface to a nadir, followed by a moderate rise that stead-

ied near the contact with the mortar. The figure also gives the third-degree polynomials

entered in the model to which the [elastic modulus (y) versus distance (x) between the ITZ

2

and the aggregate] curves were fitted with a very high correlation coefficient (R . 0.95).

The ITZ thickness entered in the model was 30 μm, as shown in Fig. 15.12. That value

was within the range (10 50 μm) assumed by other authors in similar simulations

(Zouaoui et al., 2017). The thickness was assumed to be uniform around the entire perim-

eter and the Poisson coefficient to be 0.2, in keeping with prior studies (Grondin and

Matallah, 2014).

3. Cement matrix (mortar): on the microscale this phase is a heterogeneous material com-

prising fines aggregates, cement matrix and pores. In meso-scale numerical simulations,

however, it is assumed to be homogeneous (Yaghoobi et al., 2017).