Page 540 - New Trends in Eco efficient and Recycled Concrete

P. 540

488 New Trends in Eco-efficient and Recycled Concrete

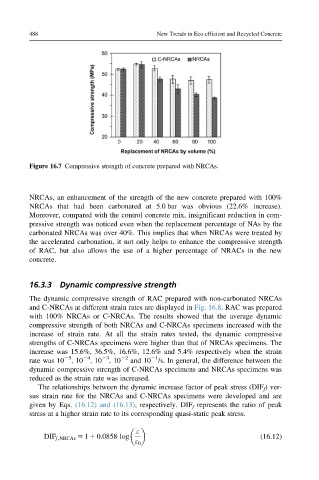

Figure 16.7 Compressive strength of concrete prepared with NRCAs.

NRCAs, an enhancement of the strength of the new concrete prepared with 100%

NRCAs that had been carbonated at 5.0 bar was obvious (22.6% increase).

Moreover, compared with the control concrete mix, insignificant reduction in com-

pressive strength was noticed even when the replacement percentage of NAs by the

carbonated NRCAs was over 40%. This implies that when NRCAs were treated by

the accelerated carbonation, it not only helps to enhance the compressive strength

of RAC, but also allows the use of a higher percentage of NRACs in the new

concrete.

16.3.3 Dynamic compressive strength

The dynamic compressive strength of RAC prepared with non-carbonated NRCAs

and C-NRCAs at different strain rates are displayed in Fig. 16.8. RAC was prepared

with 100% NRCAs or C-NRCAs. The results showed that the average dynamic

compressive strength of both NRCAs and C-NRCAs specimens increased with the

increase of strain rate. At all the strain rates tested, the dynamic compressive

strengths of C-NRCAs specimens were higher than that of NRCAs specimens. The

increase was 15.6%, 36.5%, 16.6%, 12.6% and 5.4% respectively when the strain

21

23

24

25

rate was 10 ,10 ,10 ,10 22 and 10 /s. In general, the difference between the

dynamic compressive strength of C-NRCAs specimens and NRCAs specimens was

reduced as the strain rate was increased.

The relationships between the dynamic increase factor of peak stress (DIF f ) ver-

sus strain rate for the NRCAs and C-NRCAs specimens were developed and are

given by Eqs. (16.12) and (16.13), respectively. DIF f represents the ratio of peak

stress at a higher strain rate to its corresponding quasi-static peak stress.

ε

DIF f;NRCAs 5 1 1 0:0858Ulog (16.12)

ε 0