Page 539 - New Trends in Eco efficient and Recycled Concrete

P. 539

Sequestration of carbon dioxide by RCAs 487

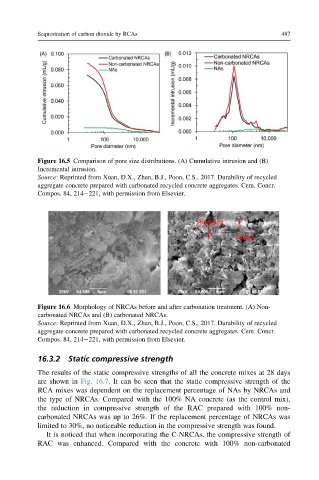

Figure 16.5 Comparison of pore size distributions. (A) Cumulative intrusion and (B)

Incremental intrusion.

Source: Reprinted from Xuan, D.X., Zhan, B.J., Poon, C.S., 2017. Durability of recycled

aggregate concrete prepared with carbonated recycled concrete aggregates. Cem. Concr.

Compos. 84, 214 221, with permission from Elsevier.

Figure 16.6 Morphology of NRCAs before and after carbonation treatment. (A) Non-

carbonated NRCAs and (B) carbonated NRCAs.

Source: Reprinted from Xuan, D.X., Zhan, B.J., Poon, C.S., 2017. Durability of recycled

aggregate concrete prepared with carbonated recycled concrete aggregates. Cem. Concr.

Compos. 84, 214 221, with permission from Elsevier.

16.3.2 Static compressive strength

The results of the static compressive strengths of all the concrete mixes at 28 days

are shown in Fig. 16.7. It can be seen that the static compressive strength of the

RCA mixes was dependent on the replacement percentage of NAs by NRCAs and

the type of NRCAs. Compared with the 100% NA concrete (as the control mix),

the reduction in compressive strength of the RAC prepared with 100% non-

carbonated NRCAs was up to 26%. If the replacement percentage of NRCAs was

limited to 30%, no noticeable reduction in the compressive strength was found.

It is noticed that when incorporating the C-NRCAs, the compressive strength of

RAC was enhanced. Compared with the concrete with 100% non-carbonated