Page 73 - New Trends in Eco efficient and Recycled Concrete

P. 73

48 New Trends in Eco-efficient and Recycled Concrete

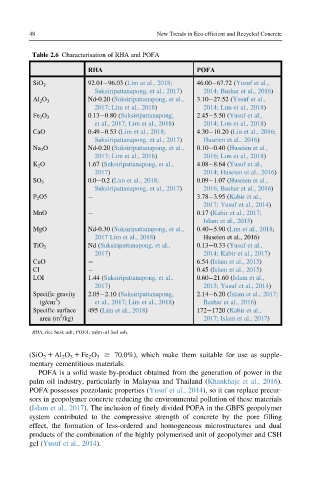

Table 2.6 Characterisation of RHA and POFA

RHA POFA

SiO 2 92.01 96.03 (Lim et al., 2018; 46.00 67.72 (Yusuf et al.,

Suksiripattanapong, et al., 2017) 2014; Bashar et al., 2016)

Al 2 O 3 Nd-0.20 (Suksiripattanapong, et al., 3.10 27.52 (Yusuf et al.,

2017; Lim et al., 2018) 2014; Lim et al., 2018)

Fe 2 O 3 0.13 0.80 (Suksiripattanapong, 2.45 5.50 (Yusuf et al.,

et al., 2017; Lim et al., 2018) 2014; Lim et al., 2018)

CaO 0.49 0.53 (Lim et al., 2018; 4.30 10.20 (Liu et al., 2016;

Suksiripattanapong, et al., 2017) Huseien et al., 2016)

Na 2 O Nd-0.20 (Suksiripattanapong, et al., 0.10 0.40 (Huseien et al.,

2017; Lim et al., 2018) 2016; Lim et al., 2018)

K 2 O 1.67 (Suksiripattanapong, et al., 4.08 8.64 (Yusuf et al.,

2017) 2014; Huseien et al., 2016)

0.0 0.2 (Lim et al., 2018; 0.09 1.07 (Huseien et al.,

SO 3

Suksiripattanapong, et al., 2017) 2016; Bashar et al., 2016)

P 2 O5 3.78 3.95 (Kabir et al.,

2017; Yusuf et al., 2014)

MnO 0.17 (Kabir et al., 2017;

Islam et al., 2015)

MgO Nd-0.30 (Suksiripattanapong, et al., 0.40 5.90 (Lim et al., 2018;

2017 Lim et al., 2018) Huseien et al., 2016)

TiO 2 Nd (Suksiripattanapong, et al., 0.13 0.33 (Yusuf et al.,

2017) 2014; Kabir et al., 2017)

CuO 6.54 (Islam et al., 2015)

Cl 0.45 (Islam et al., 2015)

LOI 1.44 (Suksiripattanapong, et al., 0.60 21.60 (Islam et al.,

2017) 2015; Yusuf et al., 2014)

Specific gravity 2.05 2.10 (Suksiripattanapong, 2.14 6.20 (Islam et al., 2017;

3

(g/cm ) et al., 2017; Lim et al., 2018) Bashar et al., 2016)

Specific surface 495 (Lim et al., 2018) 172 1720 (Kabir et al.,

2

area (m /kg) 2017; Islam et al., 2017)

RHA, rice husk ash; POFA, palm oil fuel ash.

(SiO 2 1 Al 2 O 3 1 Fe 2 O 3 $ 70.0%), which make them suitable for use as supple-

mentary cementitious materials.

POFA is a solid waste by-product obtained from the generation of power in the

palm oil industry, particularly in Malaysia and Thailand (Khankhaje et al., 2016).

POFA possesses pozzolanic properties (Yusuf et al., 2014), so it can replace precur-

sors in geopolymer concrete reducing the environmental pollution of these materials

(Islam et al., 2017). The inclusion of finely divided POFA in the GBFS geopolymer

system contributed to the compressive strength of concrete by the pore filling

effect, the formation of less-ordered and homogeneous microstructures and dual

products of the combination of the highly polymerised unit of geopolymer and CSH

gel (Yusuf et al., 2014).