Page 111 - Offshore Electrical Engineering Manual

P. 111

98 CHAPTER 8 Electric Cables

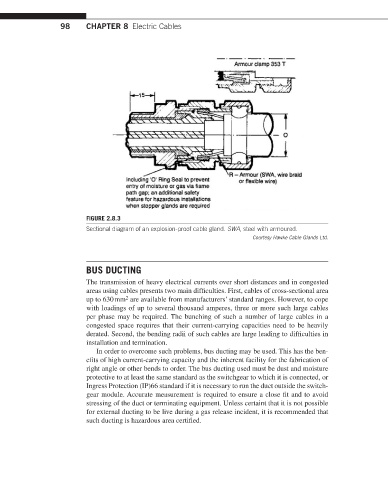

FIGURE 2.8.3

Sectional diagram of an explosion-proof cable gland. SWA, steel with armoured.

Courtesy Hawke Cable Glands Ltd.

BUS DUCTING

The transmission of heavy electrical currents over short distances and in congested

areas using cables presents two main difficulties. First, cables of cross-sectional area

2

up to 630 mm are available from manufacturers’ standard ranges. However, to cope

with loadings of up to several thousand amperes, three or more such large cables

per phase may be required. The bunching of such a number of large cables in a

congested space requires that their current-carrying capacities need to be heavily

derated. Second, the bending radii of such cables are large leading to difficulties in

installation and termination.

In order to overcome such problems, bus ducting may be used. This has the ben-

efits of high current-carrying capacity and the inherent facility for the fabrication of

right angle or other bends to order. The bus ducting used must be dust and moisture

protective to at least the same standard as the switchgear to which it is connected, or

Ingress Protection (IP)66 standard if it is necessary to run the duct outside the switch-

gear module. Accurate measurement is required to ensure a close fit and to avoid

stressing of the duct or terminating equipment. Unless certaint that it is not possible

for external ducting to be live during a gas release incident, it is recommended that

such ducting is hazardous area certified.