Page 83 - Oil and Gas Production Handbook An Introduction to Oil and Gas Production

P. 83

Maintenance Management

Asset ERP-System

Condition Create work order

Document Work order history

MMS

C

Messenger CMMS* * Maintenance status

Preventive maintenance,…

Asset Monitor

Operator Service staff

extern

Diagnosis

and

Status Data

Actuator/

Valve Heat Exchanger

Maximize the utilization of

plant assets over their lifecycle

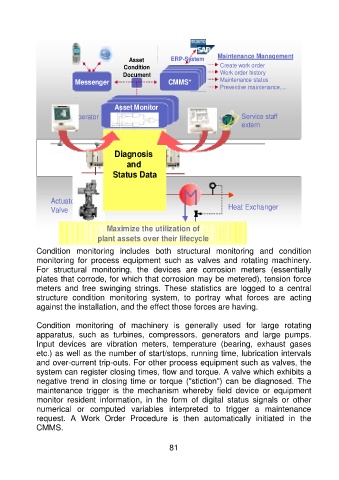

Condition monitoring includes both structural monitoring and condition

monitoring for process equipment such as valves and rotating machinery.

For structural monitoring, the devices are corrosion meters (essentially

plates that corrode, for which that corrosion may be metered), tension force

meters and free swinging strings. These statistics are logged to a central

structure condition monitoring system, to portray what forces are acting

against the installation, and the effect those forces are having.

Condition monitoring of machinery is generally used for large rotating

apparatus, such as turbines, compressors, generators and large pumps.

Input devices are vibration meters, temperature (bearing, exhaust gases

etc.) as well as the number of start/stops, running time, lubrication intervals

and over-current trip-outs. For other process equipment such as valves, the

system can register closing times, flow and torque. A valve which exhibits a

negative trend in closing time or torque ("stiction") can be diagnosed. The

maintenance trigger is the mechanism whereby field device or equipment

monitor resident information, in the form of digital status signals or other

numerical or computed variables interpreted to trigger a maintenance

request. A Work Order Procedure is then automatically initiated in the

CMMS.

81