Page 106 - Open-Hole Log Analysis and Formation Evaluation

P. 106

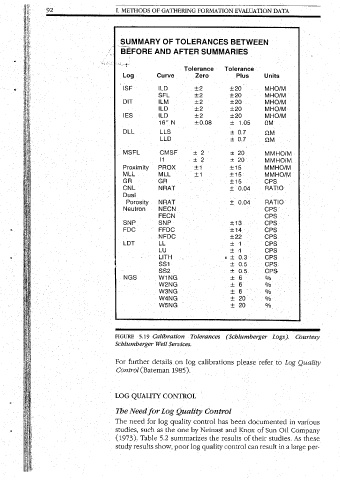

- studies, The The LOG For FIGURE LDT FDC SNP Dual CNL GR MLL. MSFL DLL IES DIT ISF Log ‘ I.

study

NGS

(1973).

-

need

Neutron

Porosity

Proximity

further

5.19

. BEFORE ‘SUMMARY METHODS

results

such

Schlumberger

_ LL GR 4 OF

for

Table

QUALITY

as

LU

log

5.2

. NRAT MLL PROX CMSF LLD LLS 16” N ILD ILD ILM SFL ILD Curve AND OF

Control (Bateman

SS1

SS2

SNP

details

LITH

show,

Need for Log

FFDC

NRAT

FECN

the

NFDC

NECN

W3NG

W2NG

WING

W5NG

W4NG

:

|.

on

Calibration

— AFTER GATHERING

_. CPS CPS ‘ + 0.04 RATIO me + 0.04 RATIO . #15 CPS +1 +15 MMHO/M — +4 #15- MMHO/M MMHO/M +2 + 20° +. 20 MMHOIM - #20 + 0.7 2M + 07 QM +0.08 + 1.05 QM +2 +20 MHO/M +2 +20 MHO/M- MHO/M +2 +20 +2 +20 MHO/M +20 MHO/M #2 Zero Plus Units Tolerance Tolerance’. SUMMARIES TOLERANCES FORMATION EVALUATION DATA 93

one

poor

1985).

Well Services.

quality

log

CONTROL

by

log

Quality

summarizes

control

the

.Tolerances

Neinast

quality

has

Control

+

+

+

calibrations

+

+

and

+ 6

+4

4

+22

#13

+14

results

+6

6

been

20

+20

control

0.5

«+03

0.5.

of

°°.

Knox

please

can

of

their

(Schlumberger

BETWEEN

%

°.°.%

%

%

%

refer

CPS

CPS

CPS

result

CPS

CPS

Sun

CPS

CPS

CPS

to

in

documented

Oil

Logs).

a

studies.

in

Log

As

large

per-

these

various

Company

Courtesy

Quality

If

to

of

be

the

the

the

go

time.

No

there

Verden

the

before

quality

Source:

during

quality

After

Sonic

smooth

bottom

tracted.

there

centage

logs

a

Density

Density

Density

objective

company

Neutron

It is the

minimum

recording

formation

is

back

Even

the

responses,

Induction

this degree

is

logging

logging

of

Upper Valley

}

Field,

Calibrations

matter

in

in

each

Give

done after the

the

depth-related

to

impossible

are ways

errors

errors

control

any

logging

Practical Log

are

Reprinted

the

the

crew

logs

the

errors

logs

available.

to

Field,

logging

obtained

log

logs

.

in

the best

0.02

0.01

the

0.01

personnel

get

log.is

rigs

are

engineer

-10

hole

Utah

operation.

Oklahoma

equipment

develop

hole should be

of the well. Do

interruption.

Learn

expect a representative

being

error

question

Quality

g/cc

g/cc

g/cc

first print is

only

with

after

not

procedures

engineer

in

company’s

operation

of the

“remarks”

mmho

down.

before

a

how competent

what

function of the well

another

engineers

by permission

is

are

failure,

Logging

about

best

complete,

and

and

thoroughly as possible. Ask for an

whom

Checks

measurements

or

error.

they

46%

36%

may

rigging

33%

15%

25%

23%

46%

distract

of the

log quality also depends

in which bad logs can

column

when

relationships

chance

engineer.

after

will

completely

you

the

Generally

on

hole

resistivity

to

available

validity,

quality.

the

mean

make

discuss

down,

the

to be available-and

the

of the

operations

in

enough to verify the

200

it

tool

work.

and

ft

but

explanation

job.

log

SPWLA from

of mutual

survey

Frequently,

Perhaps

include

log.

is

logging

conscientious

objective

in the

perform

of

request

with

should

problems,

The

how

an

a

once

100%

the

56%

the

81%

61%

render them useless as formation

43%

26%

one

78%

Bateman

the

to

Further

of any

be

Neinast

within

the

and

or

heading.

repeat

mistakes when

most

pipe

trust with

logging

engineer

use

most

operator’s representative to

and

rerun

made but before any more prints

in

is

errors

: Texas . Big Wells Field, Schlumberger Dresser Atlas Welex of Log Quality Study by Sun Oil TABLE 5.2 Results 5. WIRELINE LOGGING OPERATIONS

type.

competence and

1000

observer

(1985).

of

the

This

more

details

enter

verifications

are

ft

set,

of any abnormal

Knox

they are

operation

critical

them.

the

during

ensure

of

of

the

engineer

_—

—

_

made.

33%

T'

58%

70%

67%

1973.

he

evaluation tools.

curve

it wil!

in

repeat

dis-

log

made.

may be,

in-

relatively

Everyone is reluctant

may be

log

defy detection at the wellsite. To

logging

log

integrity

important

as

Service-company personnel

unit during

that

discussed with

this

with

time

of the