Page 34 - Optofluidics Fundamentals, Devices, and Applications

P. 34

Basic Micr ofluidic and Soft Lithographic Techniques 15

High-resolution

Light transparency

Si

Photoresist

(a) Perform photolithography

Si Master

(b) Pour PDMS over master;

cure at 70°C for 1h

PDMS

Si

(c) Peel PDMS from master

PDMS

(d) Seal against a flat surface

Microchannel

PDMS

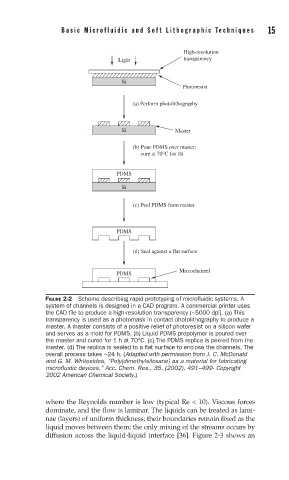

FIGURE 2-2 Scheme describing rapid prototyping of microfl uidic systems. A

system of channels is designed in a CAD program. A commercial printer uses

the CAD fi le to produce a high-resolution transparency (~5000 dpi). (a) This

transparency is used as a photomask in contact photolithography to produce a

master. A master consists of a positive relief of photoresist on a silicon wafer

and serves as a mold for PDMS. (b) Liquid PDMS prepolymer is poured over

the master and cured for 1 h at 70°C. (c) The PDMS replica is peeled from the

master. (d) The replica is sealed to a fl at surface to enclose the channels. The

overall process takes ~24 h. (Adapted with permission from J. C. McDonald

and G. M. Whitesides, “Poly(dimethylsiloxane) as a material for fabricating

microfluidic devices,” Acc. Chem. Res., 35, (2002), 491–499 . Copyright

2002 American Chemical Society.)

where the Reynolds number is low (typical Re < 10). Viscous forces

dominate, and the flow is laminar. The liquids can be treated as lami-

nae (layers) of uniform thickness; their boundaries remain fixed as the

liquid moves between them; the only mixing of the streams occurs by

diffusion across the liquid-liquid interface [36]. Figure 2-3 shows an